Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

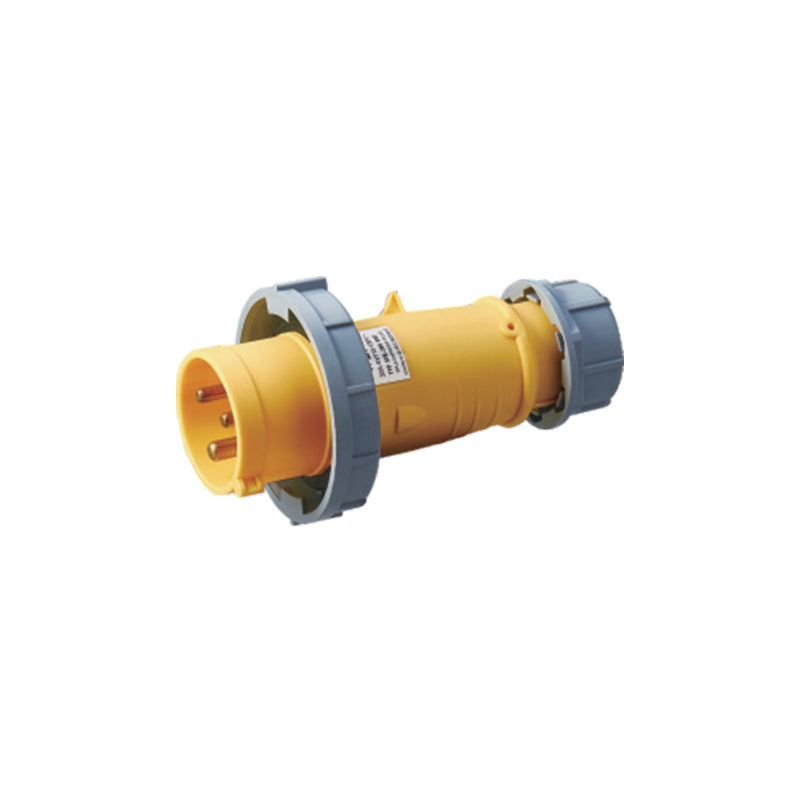

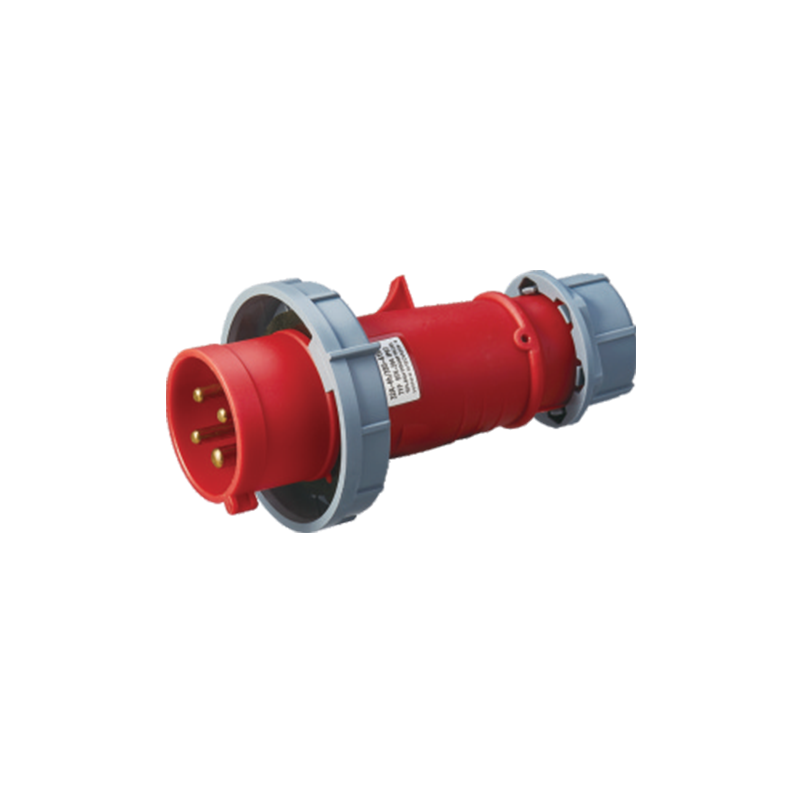

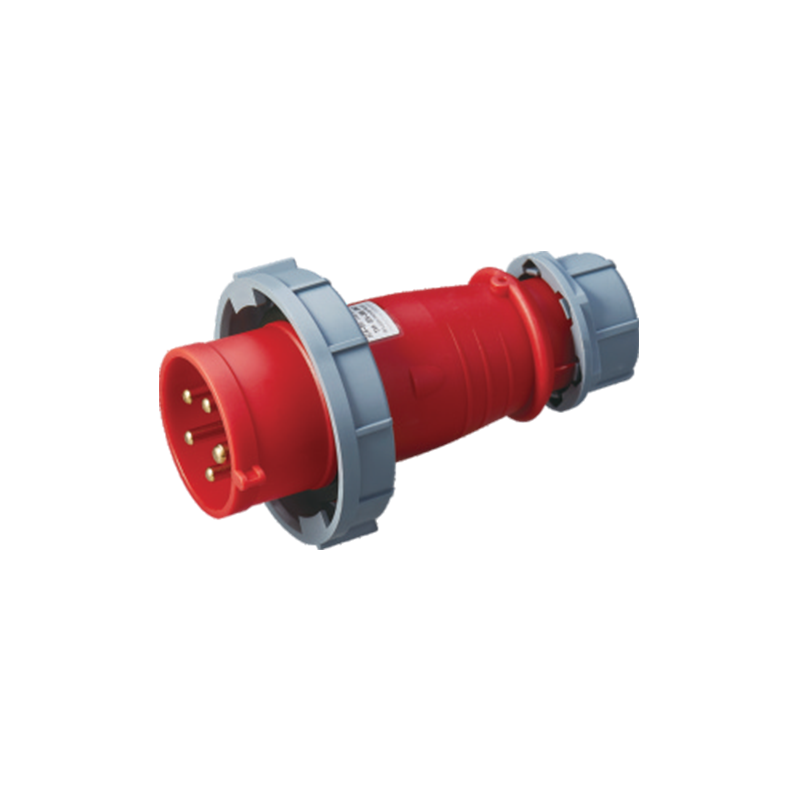

Industrial Plugs and High Current Plugs And Sockets are key parts of electrical systems that carry heavy loads. Testing these parts often is very important. It helps them last longer, work reliably, and lowers the chance of electrical problems. Knowing why testing is good and how to do it helps workers manage these parts well. This makes sure they work as they should, even in tough conditions.

Finding Early Signs of Damage

Testing on a schedule lets users find early signs of wear, rust, or physical stress. High current plugs and sockets are used again and again. They are plugged in and pulled out. They handle different amounts of electricity. Over time, this can damage the contact surfaces and the insulation. By doing regular checks for voltage and continuity, workers can find spots where electrical resistance is getting higher. They can also see where the shape of the plug has changed. Finding these problems early stops small issues from becoming big failures. Big failures can stop work and be unsafe.

Checking How Well the Contacts Work

The contacts are the important part of industrial plugs. How they work directly affects the flow of electricity and the heat that is made. Regular testing checks the contact resistance and their alignment. This makes sure the plugs stay connected securely when power is flowing. High current plugs and sockets with high resistance can get too hot in one spot and work less efficiently. So, watching the contact performance is very important. Using special tools for testing is a good idea. Tools like micro-ohm meters or thermal cameras give exact information about the contacts. They show the true health of the connection.

Keeping the Insulation Strong

The insulation is another very important part for making plugs last. Regular insulation testing finds weakening. This weakening can happen because of temperature changes, water, or chemicals. High current plugs and sockets with weak insulation are risky. They can cause short circuits or let electricity leak. Testing the insulation resistance shows if a plug is still safe to use. It tells you when to change a damaged part. This keeps electrical safety at a steady level.

Helping with Load Management and Safety

Testing high current plugs while they are working tells you how they act under different loads. Checking the voltage drop, current capacity, and heat response makes sure the plugs and sockets are working within safe limits. This information can help you decide how to work better. For example, you might run a machine for a shorter time. Or you might switch plugs between different circuits. This stops the parts from being overworked. Checking all the time also makes the whole workplace safer. This is because you can fix possible electrical dangers before an accident happens.

Planning Maintenance to Prevent Problems

The information you get from regular testing helps you plan good preventive maintenance. Instead of waiting for something to break, workers can plan inspections, cleaning, and part changes based on real wear and performance. High current plugs and sockets work better with scheduled maintenance. This maintenance uses test results to decide what to do. It makes sure that connectors, seals, and locking parts keep working for a long time. Writing down test results lets you track the history of each plug. This helps you make smart choices about when to do maintenance and when to replace a plug.

How Testing is Used in Real Situations

Regular testing is especially useful in certain places. This includes places with changing voltage needs, outdoor sites, and heavy factories. By making testing a normal part of the work routine, facilities can keep a steady flow of electricity to their machines. This reduces work stoppages and helps plugs live longer. High current plugs and sockets that are checked and cared for often are safer to use. Their performance is also more predictable. This helps the whole operation run more smoothly.

Testing industrial plugs and high current sockets often is a very good practice. It helps find wear, check contacts, keep insulation strong, manage electrical loads, and plan maintenance. All these steps help the plugs work well and last a long time. They let equipment run properly for more years. They also cut down on surprise breakdowns. Making testing a regular job is not hard, but the benefits are very big. It saves money in the long run. It also makes everyone safer. For any business that uses a lot of power, this is a simple and smart way to protect their tools and their work. In the end, a small amount of time spent testing can prevent a very big and costly problem later on.