Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

Industrial Plugs and High Current Plugs And Sockets are very important in many factories and worksites. In these places, different machines often need different amounts of voltage to work. These plugs and sockets must be able to handle these different voltage needs. This is key for keeping performance steady and for safety. Knowing how they do this helps people keep their work running smoothly. It also helps protect the machines and the workers.

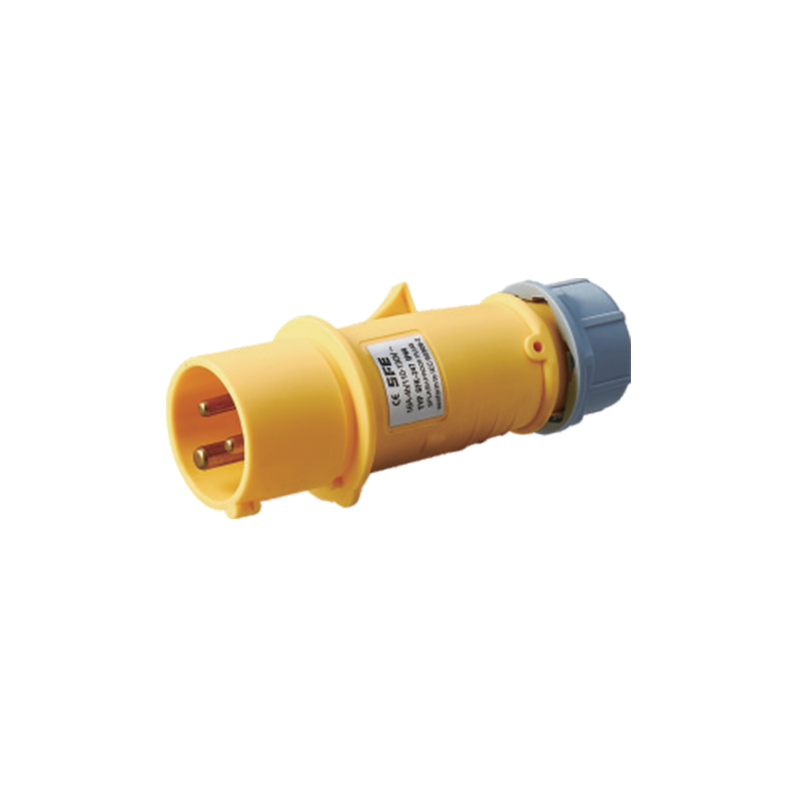

Design That Handles Different Voltages

The way industrial plugs are made inside lets them work with different voltages. High current plugs and sockets are built with special contacts and insulation. These parts are made for specific voltage levels. This makes sure the electricity flows in a stable way under different conditions. Many plugs have a modular design. This means you can choose the right contacts and connectors for your machine's voltage needs. These design choices lower the chance of overheating or electrical shorts. This is especially important when you switch between devices that use different power.

Following Standards For Compatibility

Industrial plugs often follow common standards for voltage and current. This makes them work with many kinds of machines and building systems. Because they follow these international rules, high current plugs and sockets can support many voltage levels. You do not need to change them much. This is good for users. They can connect different equipment safely. They can also keep the electrical performance steady. This compatibility makes installation simpler. It also makes mistakes less likely when connecting devices that use different voltages.

Using Connectors and Adapters

Sometimes, a machine needs to work with more than one voltage level. For this, you can use industrial plugs with special connectors or adapters. These parts let one plug handle different input voltages. They do this by providing a secure connection and the right alignment for the contacts. High current plugs often have contacts you can change. This allows for quick adjustments. This is very useful in places where voltage needs change from one workstation to another. Using adapters and connectors the right way makes sure the electrical current is spread evenly. This stops damage to both the plug and the machine it is connected to.

Watching For Safety

Changes in voltage can change how hot an industrial plug gets. They can also change how well it works. If you do not manage this, it can be a problem. Using monitoring systems can help. These systems include voltage testers and heat sensors. They give users information about the current flow and points that might be under stress. High current plugs and sockets made for multi-voltage use often have extra safety features. These can include stronger insulation, good grounding systems, and secure locks. These features lower the risks that come with electrical changes. Paying attention to voltage conditions helps workers adjust connections when they need to. This keeps the plugs working well for a long time.

Maintenance For Voltage Changes

Doing regular maintenance helps industrial plugs adapt to different voltages safely. You should clean the contacts. You should check the insulation for damage. You should also look for signs of wear or rust. This helps make sure the plugs work consistently, even under different electrical loads. Some parts will wear out over time, especially if they face repeated voltage changes. These parts might need to be replaced on a schedule. This keeps the contact good and stops electrical resistance from building up. It is also a good idea to write down the voltage ranges and history for each plug. This helps you plan maintenance. It also helps you guess about problems before they happen.

How They Are Used In Real Situations

In factories and industrial sites, you will find many kinds of equipment. Some machines, like control panels, use low voltage. Other machines, like big motors, use high power. Plugs and sockets that can handle many voltages let all these systems work together easily. This makes operations more flexible. You do not need a different kind of connector for every single device. Because they can adjust to voltage needs well, industrial plugs support steady work in many areas. This includes manufacturing, construction, and moving materials. They do this without making things more complicated than they need to be.

Industrial plugs and high current sockets are made to adapt to different voltages. They do this through smart design, following standards, using the right parts, and careful maintenance. This gives you steady electrical performance. People who know how to match plugs to voltage needs, and who watch the working conditions, can have safe and smooth operations. These good practices help keep equipment running. They also protect the work environment. This supports continuous work without unexpected stops. In the end, understanding and using these plugs correctly is a simple way to make your whole operation stronger and more reliable. It is a basic part of modern industrial work that should not be forgotten. Taking these steps ensures that power flows where it is needed, safely and without interruption.