Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

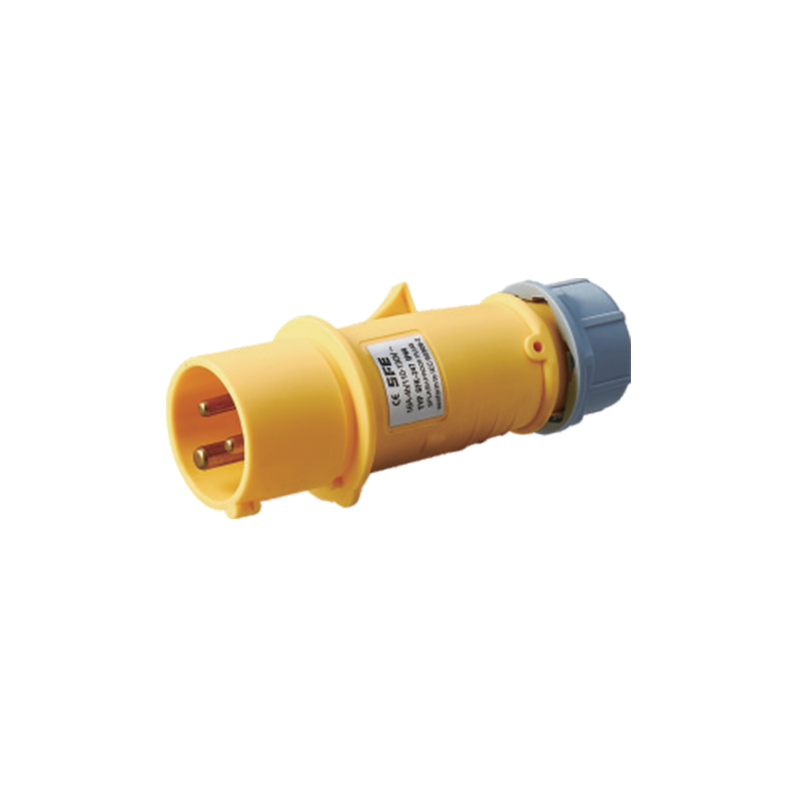

Industrial Plugs and High Current Plugs And Sockets are very important for places that need power all the time. To make sure these parts work well for a long time, you must take good care of them. Good care makes the plugs and sockets last longer. It also makes work safer and more steady in tough factory conditions.

Check Often for Wear and Damage

Looking at the plugs regularly is a key step. After much use, connectors and contacts can show signs of wear, rust, or physical damage. This can happen because they are used again and again or are in rough places. You should look for color changes, cracks, or parts that are not tight. Finding these problems early helps a lot. For high current plugs and sockets, even small problems with the contacts can change how the power flows and make overheating more likely. Planning to check them at regular times helps fix issues before they stop your work. You should also check if the pins and sockets line up right. Even a small misalignment can cause bad electrical contact. This causes more resistance and heat in one spot.

Clean to Remove Dirt

Dust, grease, and water can build up on industrial plugs and sockets. This hurts their electrical performance. Cleaning these parts with the right, mild solutions stops build-up that can make contact poor. When you work with high current plugs, do not use rough tools or strong chemicals. These can harm the surface of the contacts. You can use compressed air to blow away loose dirt in small spaces. You can also use special contact cleaning sprays made for electrical parts. This keeps conductivity good. Making sure plugs are dry and have no foreign stuff on them keeps the electrical connection steady. It also makes a short circuit less likely. For outside or wet places, you can use extra protective coatings or dielectric grease. This stops metal contacts from rusting.

Handle and Connect Them the Right Way

How you connect and unplug industrial plugs matters a lot for how long they last. For high current plugs and sockets, you should push in or pull out the connectors with steady and careful force. This stops the pins from bending or changing shape. Do not twist or pull too hard. This protects the parts inside and the locking parts. Also, make sure the plugs are lined up right with the sockets before you push them together. This makes them wear less and makes work safer. People using them should learn to feel if there is unusual resistance or stiffness when connecting. This can be an early sign of dirt inside or misalignment. Using the correct force to tighten screws or clamps keeps connections secure without hurting the parts.

Watch the Temperature and Load

Factory work often uses heavy electrical loads. This can make heat at the connection points. Watching the temperature around plugs and sockets can help you find stressful conditions that might hurt performance. High current plugs are especially sensitive to high heat. Heat can slowly break down the insulation or contacts. Using the devices within their suggested load limits and noticing any strange heating patterns helps them run well for a long time. Putting thermal sensors or infrared cameras in important spots lets you find hot areas early, before damage happens. Writing down the working temperatures now and then also helps plan maintenance and know when to change parts.

Change Parts When Needed

Even with good care, some parts of industrial plugs will wear out in the end. Contacts, seals, and locking parts can stop working well over time. Changing worn or damaged parts on a schedule keeps the electrical connection strong. Many industrial plugs are made in sections. This lets you change only some parts without taking everything apart. This makes maintenance easier and causes less work stoppage. Keeping a supply of parts that are often changed, like pins, gaskets, and clamps, means you can fix things fast without stopping your work.

Think About Storage and the Environment

When plugs and sockets are not being used, you must store them correctly to keep them safe from the environment. Keep them in a place that is dry and has no dust. This protects them from water and rust. High current plugs get a special benefit from controlled storage. It stops the contacts from getting bent by accident or being exposed to dirt. Being careful when you store and move them can lower the need for maintenance and help them work well when you need them next. For setups that get vibration, dust, or bad air, use protective covers or boxes when the plugs are not connected. This makes them last longer.

Write Things Down and Train Your People

Keeping good notes about your checks, cleanings, part changes, and working conditions can make your industrial plugs more reliable in the long run. Writing things down helps you see how they are wearing, find problems that happen often, and plan your maintenance schedule better. Also, teaching your workers how to handle, connect, and care for high current plugs and sockets makes sure they do things the right way. Workers who know what to do can see small issues early and stop them from becoming big problems that break your work.