Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

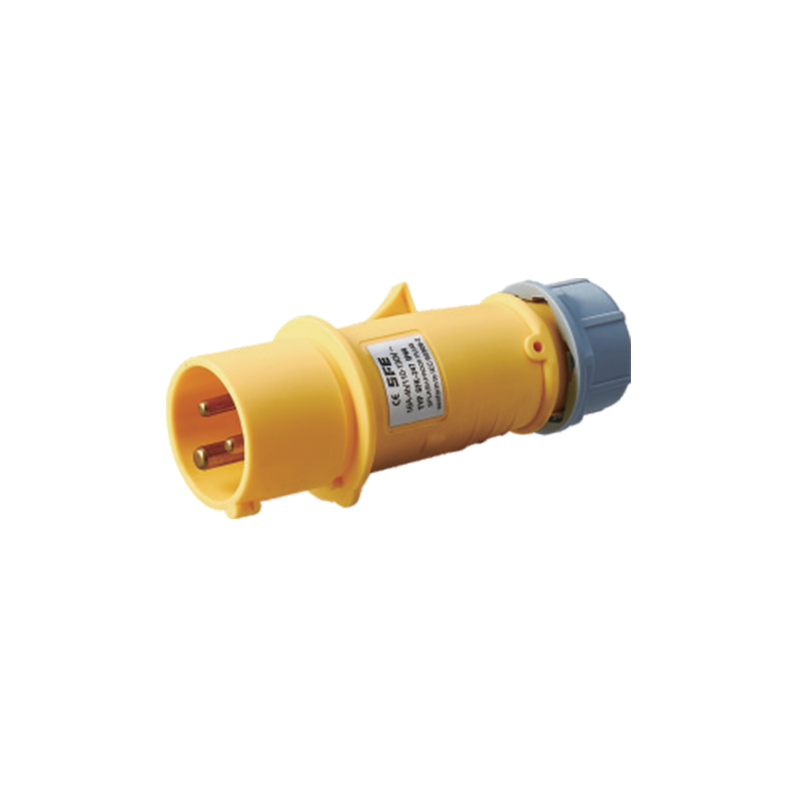

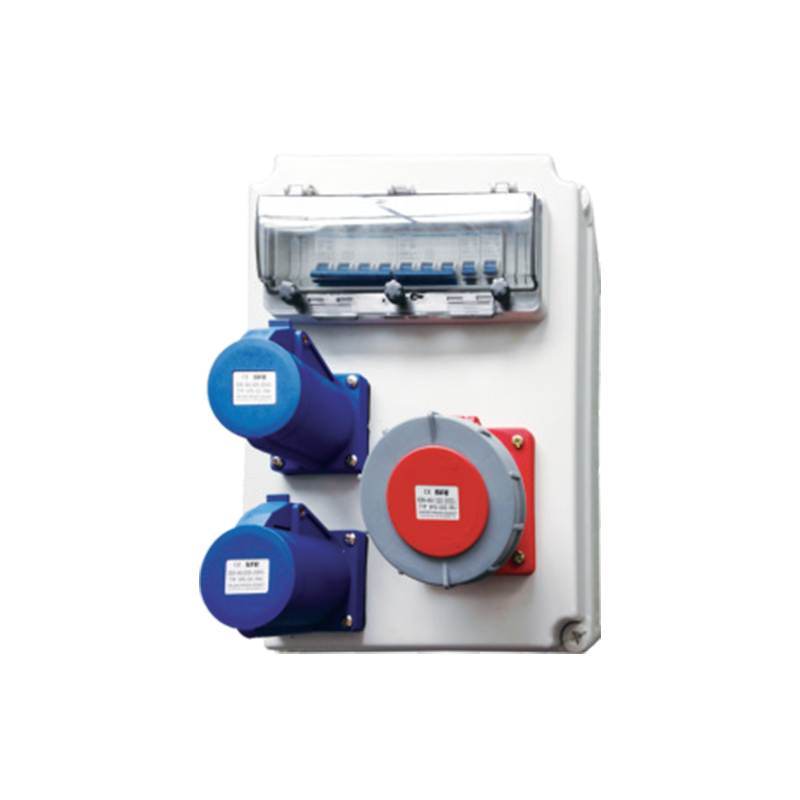

Industrial Plugs and High Current Plugs And Sockets are very important in many places. These places often need their electrical systems to change. They must work with new equipment and different power needs. Modular design is a very useful idea for this. It lets you change or improve these parts without buying a whole new unit. Knowing how modular design works can help people keep their electrical connections flexible and efficient. It also supports different work needs.

The Good Things About Modular Building

A modular design breaks industrial plugs into separate parts. These parts can be swapped. The parts include the contacts, the outer shell, and the locking pieces. This way of building means you can replace or set up each part for your specific needs. You do not have to replace the whole assembly when something changes. So, high current plugs and sockets can work with different connector sizes, power ratings, and voltage levels. They still make a secure connection. This ability to change cuts down on work stoppages. It also makes it easier to adjust things when the system needs to be different.

Easy Upgrades and Changes

Because of modular design, high current plugs and sockets can be changed for specific jobs. For example, you can add more contact pieces. Or you can change how the pins are set up. This lets the same plug work for new equipment needs. This idea is very helpful in factories and industrial sites. In these places, machines and power needs change over time. Workers can change or add to existing connections. They do not need to rewire everything. They also do not need to buy all new units. This saves both time and money.

Better and Faster Maintenance

Modular design also makes maintenance faster and better. If a single part starts to wear out, you can just replace that one part. You do not need to take apart the whole plug or socket. This kind of focused maintenance means work stops for less time. It also helps the whole assembly last longer. High current plugs and sockets that are checked and fixed this way stay stable and safe. This is very important in tough work environments.

Changing for Different Places

Industrial plugs are often used in different places. They might get wet, dusty, or face hot or cold temperatures. Modular designs let workers pick the right parts for these conditions. They can choose special shells, seals, or protective covers. By building the plug for a specific place, high current plugs and sockets keep working well and safely. They can be used on factory floors or at outdoor building sites.

Flexibility for Sending Power Where It Is Needed

Some jobs need different amounts of current or voltage for different machines. Modular plugs help with this. They let you easily change the contact setup or add more parts. This flexibility makes sure the electrical system can change when power needs change. You do not need to have many different kinds of plugs. This also makes it easier to manage your supplies. Workers can react quickly to changes in the work. They can also keep all the connections secure and efficient.

Training and How to Use Them

Knowing about the modular parts also helps people use them better. Putting the parts together the right way, checking them, and replacing them makes sure high current plugs and sockets work well and safely. Workers can see which part is worn out and change it quickly. This keeps the electrical connection strong. Teaching people how to put together and care for modular plugs makes the whole system more reliable. It does not make things more complicated.

Why This Matters for the Future

Using a modular design is a smart choice for the long term. As technology gets better, the needs for power will also change. Modular industrial plugs let you update your system without throwing away all your old parts. This is good for your budget and also good for the environment. It creates less waste. You can keep the main shell and just change the inside parts. This is a very efficient way to work.

Making a System That Can Grow

Modular parts help you build an electrical system that can grow with your business. If you need to add a new machine, you can often adapt the existing plugs. You do not always need to install completely new wiring. This makes your whole operation more scalable. You can expand your work without big, expensive electrical projects. This is a key reason why many new factories choose modular high current plugs and sockets from the start.

To sum up, modular design in industrial plugs and high current sockets is a very practical idea. It gives you flexibility, lets you customize, and makes maintenance efficient. By using parts you can swap, workers can adapt to new equipment, different environments, and changing power needs. The connections stay safe and stable. This approach supports steady operation. It also helps these important parts last longer in industrial settings. It is a simple idea with very big benefits. Making the switch to modular components can save a lot of time and money over the years. It is a smart way to build a strong and reliable electrical system for any serious industrial work. This method proves that being able to change is just as important as being strong.