Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

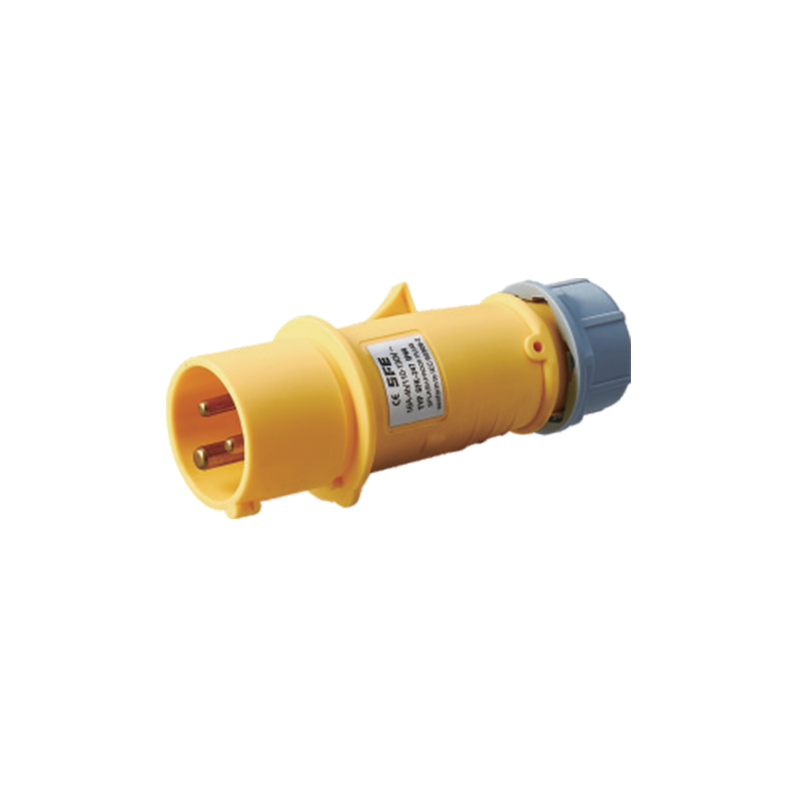

Tools often stop working unexpectedly because of poor connections. For tools and machines that run for a long time or in tough conditions, a steady flow of power is very important. A small problem can disrupt the work. Using a strong Industrial Connector with a 3-Pin Plug Socket is a good way to fix this. These parts help tools run better by providing a stable connection. Knowing how they work helps you pick the right equipment for workshops, factories, and outdoor jobs.

Stable Electrical Flow from Good Grounding

Tool stability depends a lot on grounding. A 3-Pin Plug Socket has separate points for live, neutral, and ground wires. This clear separation stops irregular current that can disrupt a tool. The grounding wire gives stray electricity a safe path to follow. This means the tool gets a steady power supply instead of power that goes up and down. Industrial tools use more power and are often used in places with lots of vibration. So, a stable ground connection is more important than for home appliances. A well-made Industrial Connector fits very securely. It keeps each pin firmly touching the socket terminal. This stops loose connections that can cause the power to flicker or the tool to restart suddenly. This steady power helps tools like drills, grinders, and testers run smoothly from start to finish.

Strong Physical Connection

Tool performance depends on both electrical and physical stability. Industrial Connectors are built to be tough. They often have strong housings, locking rings, or latches that hold the plug and socket together tightly. The design of a 3-Pin Plug Socket helps here too. The pins are spaced evenly, so the pressure is spread out when connected. Tools are often moved or used in busy areas. Cables can be pulled or bumped by accident. A good locking system stops the plug from coming loose. This prevents work stoppages. This is very useful in factories where cables are on the floor or hanging from machines. Keeping the connection secure allows for consistent operation. Workers don't have to stop and reconnect tools as often.

Better Safety for Steady Operation

Safe tools are stable tools. A 3-Pin Plug Socket improves safety with its ground wire, insulated housing, and easy-to-align pins. These features lower the risk of short circuits or electrical sparks. These problems are not just dangerous; they can also cut the power suddenly. In industrial places, power surges and heavy loads are common. A connector that is built for safety helps keep the tool running. If safety features don't shut the tool off unexpectedly, the work can continue without unwanted stops caused by electrical issues.

Working Well with Different Tools and Conditions

A connector must fit the tool and the environment to work well. The 3-pin design is common for industrial tools because it works with many power standards and machines. The Industrial Connector adds to this fit. It can have different pin layouts, protective covers, and housings for various places. When the connector fits the tool's power inlet perfectly, the connection is complete. A good fit puts less strain on the pins and socket. This helps the connection last longer and stay stable. A matching connector also makes it easy for workers to plug and unplug the tool smoothly. This prevents damage from forcing the connection.

Lasting Longer in Tough Environments

Dust and water can get into connections and cause problems. Many Industrial Connectors have sealed housings or protective rings. These seals keep dirt and moisture away from the metal contacts inside. When used with a 3-Pin Plug Socket, this protection stops the contacts from rusting or corroding. This keeps the electrical flow smooth. On construction sites or outdoors, dust and humidity are common. Using connectors that resist these conditions helps keep tools stable. The contacts stay clean and dry. Over time, this stops a slow decline in performance. It also means the tools need less repair.

Easy to Use Correctly

How easy a connector is to use affects stability. If a connector is hard to plug in, users might not connect it all the way. This causes a poor connection. Good connectors have shapes that are easy to hold, clear markings, and grip surfaces. A 3-Pin Plug Socket is simple to align. The pin layout guides the plug into the right place. This reduces mistakes. It makes sure the tool starts each job with a full and secure connection. Easy handling is good in fast workplaces where tools are moved around often.

Tools stay stable not just because of their own design, but also because of their power connection. Using a strong Industrial Connector with a well-made 3-Pin Plug Socket causes more reliable tool operation. It causes fewer work stoppages and creates a smoother workflow. In places where tool performance is critical, this combination is a very practical part of a dependable work setup.