Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

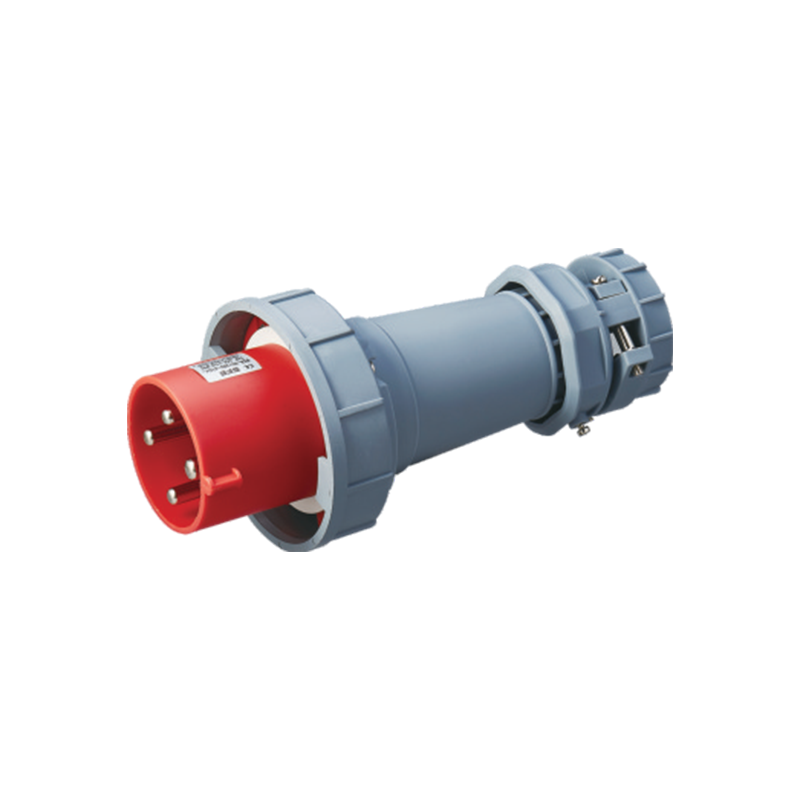

Daily power needs in workshops and job sites put steady pressure on connection systems. How an Industrial Connector and a 3-Pin Plug Socket carry and manage power affects equipment performance all day. Users need to know how connectors should work under normal loads, how to avoid stops, and how to prevent wear from long use. Knowing these things helps make work safer and more reliable.

Managing Stable Power Through Repeated Use

Daily work often means machines turn on and off many times. Tools use different amounts of power, and equipment switches between standby and active modes. The connector system must handle these changes well. It must not have loose contacts or power that jumps around.

A 3-pin socket design keeps the ground wire separate from the power wires. This helps the current flow stay even when the power need changes. The ground pin helps control voltage changes. This gives tools a steady start. An Industrial Connector has strong terminal pressure. This keeps the pin connections tight, even if the cable moves or shakes. This stability during many on-off cycles helps tools work the same way every time.

Handling Heat from Long Operating Hours

When equipment runs for many hours, the connector's contacts can get warm. Heat itself is not always a problem. But if it gets too high, it can make metal expand, increase resistance, and hurt the power connection.

Industrial connectors made for 3-pin sockets use metals that conduct electricity well and housings that can take heat. Good contact shape stops heat from warping the connection. Having air flow around the connector and using the right cable size also keeps temperatures steady. Checking the contacts often to keep them clean helps heat escape properly. These steps lower the chance of performance problems from too much heat.

Keeping a Strong Physical Connection with Movement

Many jobs require pulling cables or moving tools. Daily use puts physical stress on connectors. This can loosen terminals if the connector is not built strongly.

A 3-Pin Plug Socket has evenly spaced pins. This gives balanced support. Industrial connectors often add locking rings or latches. These stop the plug from coming out by accident. They also reduce wear from cable pulls and prevent work stoppages. Less movement at the connection point means smoother power delivery all day.

Dealing with Sudden Power Surges Safely

Tools can have sudden power surges. This happens when a motor starts or a tool hits hard material. The connector system must handle these jumps without problems.

A correctly rated Industrial Connector spreads the electrical load evenly across its contacts. This gives stable performance when power needs spike. The ground design of a 3-pin socket adds safety during surges. It helps manage unexpected voltage. For users, picking connectors with the right power rating for their normal work is a simple way to ensure steady daily operation.

Protection from Dirt, Water, and the Work Environment

Daily power use happens in real-world conditions. Dust can build up and increase resistance. Water can cause rust. Corrosive settings can weaken contacts over time. These issues build up slowly and change how power flows each day.

Industrial connectors usually have seals or protective housings. These keep the inside parts safe. When used with a 3-pin socket, this protection keeps the contact surfaces stable. It lowers problems caused by dirt and water. Even small particles can disrupt daily power if they get on the contacts. Cleaning connectors regularly and storing them properly when not in use helps power flow stay consistent.

Using the Right Cables and Ratings for Daily Work

A connector system will fail if used with cables or pins that are too small. Cables that are too small create extra heat. Cables that are too big might not fit well, causing a poor connection. Pin materials and socket shape must also be correct.

The 3-pin setup has a standard shape. Industrial connector makers offer models for different power levels. Users should match the connector rating to the tool's normal working range. Correct pairing cuts energy waste, stops strain on terminals, and supports steady performance over long hours.

Reducing Wear from Plugging and Unplugging

Daily use means connecting and disconnecting tools often. This repeated action can wear down contact surfaces over time. To handle daily power well, connectors must be plugged in fully and straight, and removed by pulling properly, not yanking the cable.

Industrial connectors for 3-pin sockets often have guide grooves or alignment marks. These make correct plug-in easier. They lower the chance of a partial connection, which is a common reason for unstable power during the day. Smooth and full engagement each time helps maintain reliable power for the life of the connector.

Keeping Power Balanced in Multi-Tool Areas

Work areas that peveral tools at once need even power distribution. An imbalance can happen if one line carries too much power, or if tools with very different needs share the same outlet. This can hurt daily performance, especially during long tasks.

Industrial connectors made for organized power distribution help keep circuits separate. When using 3-pin sockets here, consistent grounding and correct alignment keep current paths stable. Workers get predictable tool behavior, which is important for precise or long jobs.