Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

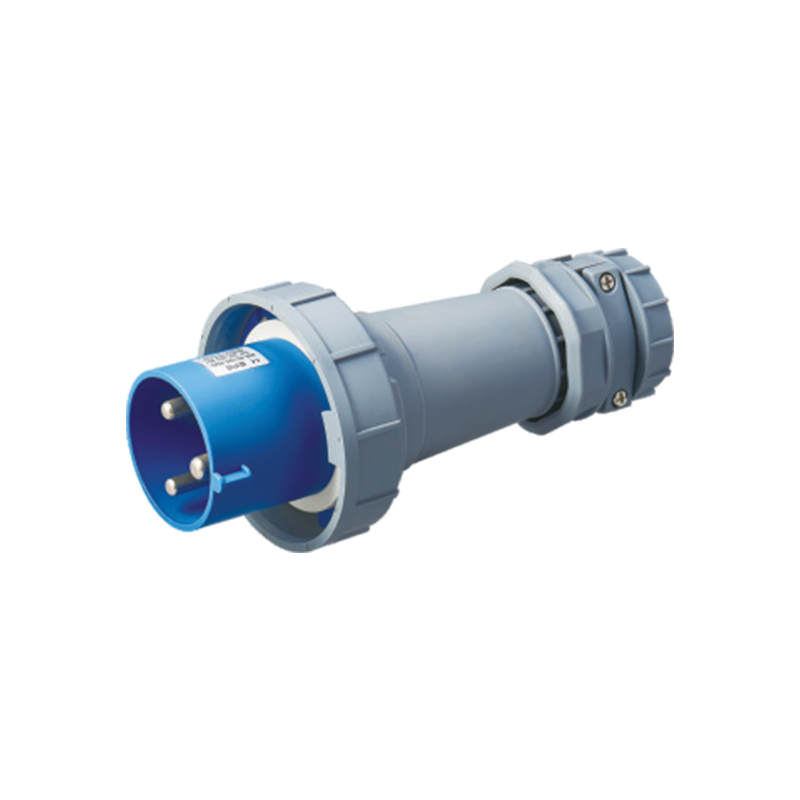

Sale High Current Industrial Plugs Male And Sockets Female

High current plugs and sockets play a crucial role in modern industrial environments. These components are specifically designed to handle the high-power demands of machinery, equipment, and industrial systems that require significant electrical currents. As industries evolve and equipment becomes more advanced, the demand for robust and reliable high current plugs and sockets continues to grow.

One of the primary functions of high current plugs and sockets is to ensure safe and efficient power distribution. In industrial settings, high-power equipment, such as motors, welding machines, and heavy-duty machinery, requires plugs and sockets capable of handling large currents without overheating or failing. High current plugs and sockets are engineered to prevent electrical faults by offering secure connections that lessen the risk of power loss or fire hazards.

When it comes to industrial applications, high current plugs and sockets are designed to meet stringent standards of safety and performance. These components are often subjected to rigorous testing to ensure they can withstand the physical demands of continuous use in harsh environments. From high temperatures to vibrations and chemical exposure, high current plugs and sockets are built to endure, providing reliable power connections for critical industrial operations.

The design of high current plugs and sockets is another key factor that determines their effectiveness in industrial applications. These components must be durable and capable of maintaining stable electrical conductivity under high currents. They are typically made from high-quality materials such as copper, brass, or specialized alloys that provide reliable conductivity and resistance to wear and tear. In addition, high current plugs and sockets feature robust insulation to prevent electrical shorts and ensure operator safety.

Another important feature of high current plugs and sockets is their ability to handle large voltage fluctuations. In industrial applications, power systems are often subjected to sudden surges or drops in voltage, which can damage sensitive equipment. High current plugs and sockets are designed to accommodate these voltage variations without compromising the integrity of the electrical system, ensuring a stable and uninterrupted power supply for industrial processes.

Furthermore, high current plugs and sockets contribute to the overall efficiency of industrial systems. By providing secure and efficient connections, these components help reduce power losses during transmission, which in turn improves the overall energy efficiency of machinery and equipment. This is particularly important in industries where energy consumption is a significant concern, such as manufacturing, construction, and mining.

High current plugs and sockets are also vital for ensuring compatibility between different types of industrial equipment. As industries utilize a wide range of machines and systems, it is essential that all components can seamlessly connect to one another. High current plugs and sockets are available in various configurations, allowing for compatibility with different electrical systems and equipment, thus enabling smooth integration into existing setups.

In addition to their practical applications, high current plugs and sockets play a role in improving the overall safety of industrial operations. Electrical accidents, such as fires or electrocution, are often caused by faulty or improper connections. By using high current plugs and sockets, industries can mitigate these risks, ensuring that all power connections are secure and capable of handling the required loads.

One of the significant advantages of high current plugs and sockets is their ease of use. Unlike traditional connectors, these components are designed for quick and simple connection and disconnection. This feature is particularly beneficial in industries where equipment must be frequently plugged in and unplugged, such as in maintenance and repair operations.

The importance of high current plugs and sockets is further highlighted in environments where heavy machinery and equipment are in constant use. For example, in manufacturing facilities, power tools and production lines require high current plugs and sockets to ensure reliable power delivery. Similarly, in construction sites and mining operations, high current plugs and sockets ensure that large machines, such as drills, excavators, and generators, remain operational under demanding conditions.

As industries continue to grow and evolve, the demand for reliable power connections will only increase. High-current plugs and sockets will remain essential components for powering a wide range of industrial equipment. Their ability to handle large electrical currents, ensure safety, and provide efficient power distribution makes them indispensable in modern industrial settings.

In conclusion, high current plugs and sockets are vital components in industrial applications, providing safe, reliable, and efficient electrical connections for a variety of heavy-duty machinery and equipment. Their durability, compatibility, and performance make them indispensable for ensuring smooth operations and preventing electrical failures in industrial environments. As industries continue to advance, the role of high current plugs and sockets will only become more critical in maintaining the integrity and efficiency of electrical systems.