Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

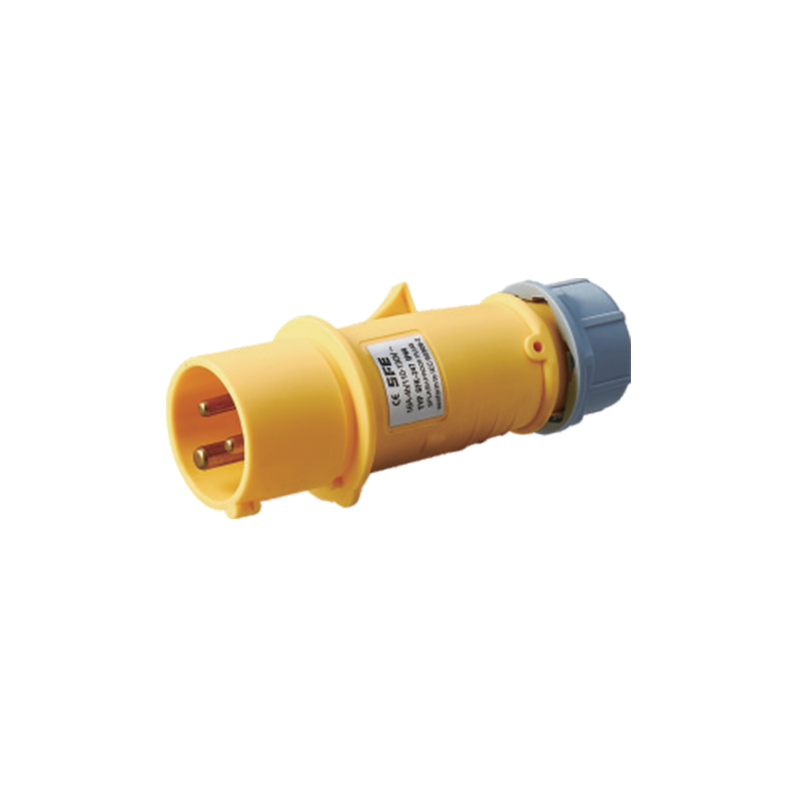

Custom High Current Industrial Plugs Male And Sockets Female

High current plugs and sockets are essential components in many industrial and commercial applications, particularly in heavy-duty equipment where power requirements are significant. These electrical connectors are designed to handle high voltages and currents, ensuring that machinery and systems operate safely and efficiently. Understanding the role and importance of high current plugs and sockets is crucial for engineers, technicians, and manufacturers involved in the design, installation, and maintenance of such equipment.

Heavy-duty equipment often requires substantial power to operate motors, hydraulic systems, and other electrical components. High current plugs and sockets are built to deliver that power safely and reliably. Their design is tailored to prevent overheating, electrical faults, or power losses that could advance to costly downtime or damage to expensive machinery. These plugs and sockets can handle the substantial electrical loads that typical residential or commercial connectors cannot manage, making them vital for large-scale operations.

The primary purpose of high current plugs and sockets is to provide a secure and stable electrical connection. In heavy-duty equipment, where the power demands are high, any interruptions or poor connections could advance to equipment failure. High current plugs and sockets offer robust connectors that ensure a continuous power supply, thereby improving operational efficiency. Their construction includes durable materials capable of withstanding harsh environments, such as high temperatures, moisture, and vibrations, which are common in industrial settings.

Moreover, high current plugs and sockets are designed with safety in mind. They feature built-in mechanisms that help prevent electrical hazards, such as short circuits and overloads. For example, many high current plugs and sockets include insulation and locking mechanisms that ensure proper alignment and prevent accidental disconnections during operation. These safety features are particularly important in environments where equipment is subjected to continuous stress or where the risk of electric shock is higher due to wet or hazardous conditions.

The durability of high current plugs and sockets is another key consideration. Heavy-duty equipment often operates in demanding environments, including construction sites, factories, and power plants. These conditions require connectors that are not only powerful but also resistant to wear and tear. High current plugs and sockets are typically made from tough materials such as thermoplastics, stainless steel, and aluminum, all of which offer resistance to corrosion, impact, and other environmental factors. This durability ensures that these components can continue to perform reliably over time, even in the more challenging conditions.

In addition to safety and durability, the design of high current plugs and sockets also takes into account ease of use and flexibility. Many heavy-duty machines and equipment require frequent maintenance or adjustments. High current plugs and sockets are designed to be easy to install and remove, allowing technicians to quickly disconnect and reconnect electrical systems without the need for specialized tools or excessive force. This user-friendly design reduces downtime during maintenance activities and helps prevent accidental damage to equipment.

Another critical factor is the compatibility of high current plugs and sockets. Heavy-duty equipment often involves complex electrical systems that require various types of connectors. High current plugs and sockets are available in different configurations and sizes to accommodate the unique needs of each application. Whether for industrial motors, large-scale generators, or mobile equipment, these connectors can be customized to meet specific power requirements, ensuring that each system operates efficiently and safely.

Furthermore, the continued development of high current plugs and sockets has led to innovations that enhance their performance. For example, advancements in materials science and electrical engineering have resulted in connectors that offer lower resistance, improved heat dissipation, and better resistance to electrical arcing. These innovations ensure that high current plugs and sockets can handle increasingly high-power applications without compromising safety or reliability.

In conclusion, high current plugs and sockets play a pivotal role in the functionality and safety of heavy-duty equipment. Their ability to manage substantial electrical loads, provide secure connections, and withstand harsh environmental conditions makes them indispensable in a variety of industrial settings. By ensuring safe, efficient, and reliable electrical connections, high current plugs and sockets contribute to the smooth operation of machinery, reduce downtime, and extend the lifespan of heavy-duty equipment. Their importance cannot be overstated, as they are integral to the success of industries that rely on heavy machinery and high-power systems.