Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

Worksites and factories need flexible power systems for changing machines. High current plugs and sockets and multi-socket panels provide steady electricity and simpler care. This guide shows how to choose and install them right.

Big Power Needs For Heavy Machines

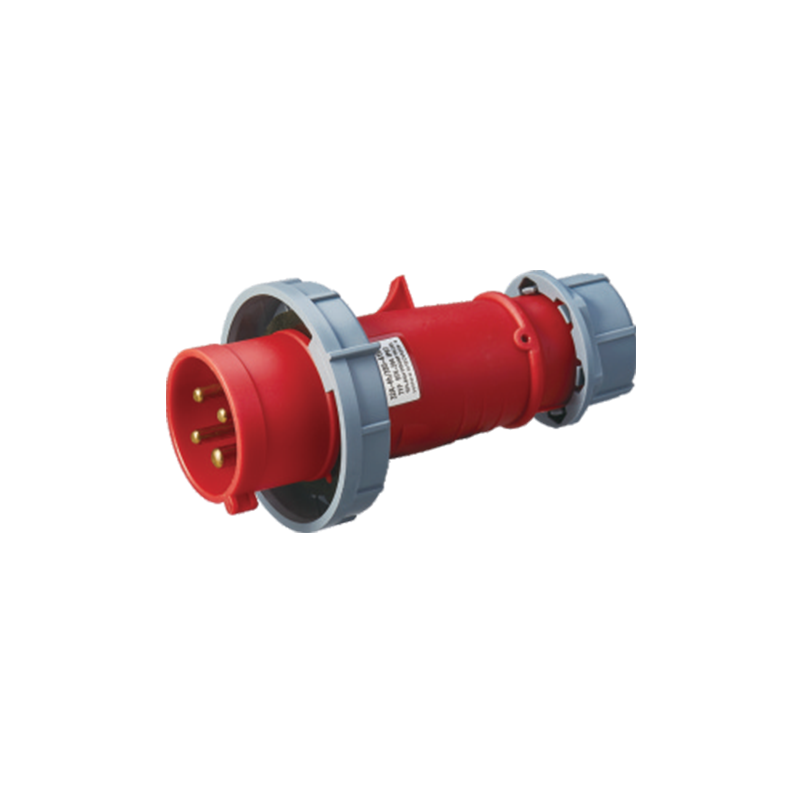

Steel mills, chemical plants, mines, and big construction sites use strong machines. These need reliable power connections. High current plugs and sockets handle big electricity flows safely. They keep metal contacts tight and stay cool during work. These parts use thick copper with special coatings. This reduces electrical resistance over long hours. Less heat means longer life.

When choosing high current plugs and sockets, check two things: power ratings and insulation. Hot areas need heat-resistant housings. Wet places need waterproof designs. Products follow ISO9001, CE, and ROHS rules. But always confirm details match your site. An indoor plug might fail outdoors.

Multi-Socket Setups Improve Work

Multi-socket units solve cable problems. Many tools plug into one power point. This reduces messy cords and organizes panels. Each socket must handle its load. Overheating risks melting parts or unplugging.

New multi-socket designs have safety features. Spring covers block dust in unused sockets. Locking rings secure plugs during shaking. Clear labels prevent wrong connections during repairs. For moving machines, special clamps hold cables firmly. This stops tug damage. Factories test each socket for even spacing and tight grips. This ensures steady power for different machines.

Good Setup Reduces Stops and Costs

Even certified high current plugs and multi-socket units fail if installed poorly. Strip wires to exact lengths. Use proper tools to clamp connections. Loose wires cause hot spots and fires.

Add rubber seals where dust exists. Use rain covers outdoors. Leave air space around boxes for cooling. Check connections monthly: look for brown burns, cracks, or loose screws. Early finds prevent big breakdowns. Follow setup guides so all workers use safe methods. Proper work cuts surprise stops and repair bills.

Where These Parts Work

High current plugs and sockets and multi-socket solutions power many places:

Ports (ship cranes)

Factories (robotic arms)

Construction (concrete pumps)

Big cranes use power panels with multiple sockets. Crews switch machines fast during shifts. Stores hide multi-socket panels in walls for backup power during changes. Tough plugs avoid rewiring each layout change. Mines use movable power boxes. These follow miners underground. Strong cases handle rock hits and temperature swings from cold tunnels to hot deserts. This keeps drills and fans running.

Buying and Care Advice

When buying multi-socket units, ask for:

Size drawings

Material lists (like sun-proof plastic)

Test reports

Check they match your safety switches. Know your cable sizes and box mounts. Plan maintenance every 3-6 months. Clean contacts with special spray. Check screws with a torque wrench. Replace cracked covers fast. Keep spare plugs to avoid delays. For foreign machines, match plug shapes to standards like IEC 60309. Never force wrong plugs – causes sparks.

Get help matching products to your site. Describe conditions: Dusty? Hot? Moving machines? Experts advise for tough spots like shipyards or airports. Clear details prevent wrong orders and risks.

Key Points for Reliability

Good power systems need:

Correctly rated high current plugs and sockets

Multi-socket units sized for total load

Weather protection matched to site

Safety locks for shaking areas

Regular cleaning and checks

This reduces fires, machine damage, and work stops. Safe connections keep projects on time and workers protected. Always test new setups before starting work.