Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

In many industrial and construction settings, maintaining consistent and organized power distribution is critical for both safety and operational continuity. Multi-socket assemblies and high current plugs and sockets play an important role in configuring worksite power panels and connecting various equipment efficiently. Wenzhou Shangfeng Electric Co., Ltd. shares practical information to help facility managers and project teams assess appropriate configurations for diverse applications.

Configuring Panels For Heavy Electrical Loads

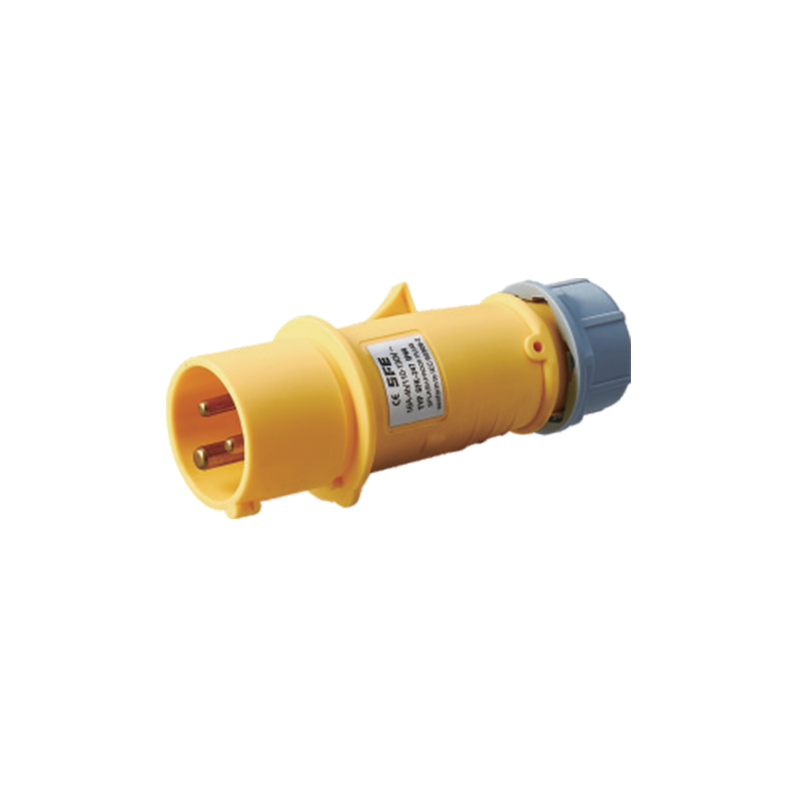

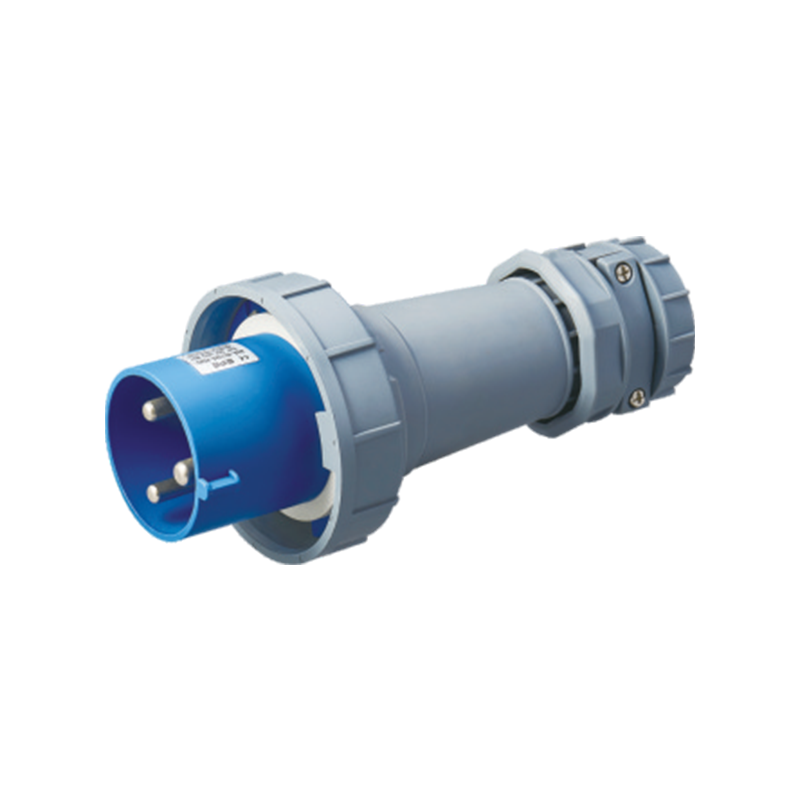

Worksites like steel mills, chemical plants, big construction jobs, and transport hubs use machines needing strong power. High current plugs and sockets carry big electrical loads safely. They make less heat and reduce wear on contact points. Multi-socket panels let many tools run from one place without rewiring.

Teams must check the power rating (current and voltage) and match local rules. Each socket needs clear labels and must handle the machine’s power. Overloading causes heat, cable damage, and work stops. Products meet ISO9001 quality and CE/ROHS safety rules.

Technical Features For Long Life And Easy Care

What plugs and sockets are made of affects how long they last. Parts facing dirt, wet conditions, shaking, or heat changes need strong plastic cases. Metal contacts often use copper with special coating to fight rust and keep power flowing well.

Multi-socket panels have safety covers and optional seals to block dirt. Fire-resistant materials and secure locks help prevent unplugging by accident or short circuits. These features keep work running and help with repairs by making connectors easy to find.

Every product is checked for size and tested to confirm it handles its rated power. Clear labels and setup guides help users wire things safely.

Setting Up And Checking To Prevent Problems

Even good high current plugs and multi-socket panels can fail if set up wrong. Prepare wires correctly: strip them right and clamp ends tightly. Leave space in panels for air to flow and stop heat buildup.

Check connections often where machines shake or cables move a lot. Brown marks or loose parts mean heat or spark risks. Finding issues early stops bigger breakdowns.

Every multi-socket outlet needs the right safety switch (breaker or fuse). Test these switches sometimes because dust, wet, or heat can change how they work.

Uses On Sites Like Building, Mining, And Ports

Multi-socket setups with high current plugs and sockets work well on building sites, tunnels, shipyards, and storage centers. For example, big concrete plants run mixers and pumps from central panels with many sockets. This cuts messy cables across sites and makes shutdowns easier during repairs.

Mining sites use movable power units with strong connectors. These get moved often and reconnected many times. Tough cases and good locks keep power steady for lights, air systems, and heavy machines.

These parts support sites worldwide where steady power keeps work safe and productive. Rules differ, but key ideas stay: match power ratings, keep connections clean, and check often.

Picking The Right Setup For Your Job

Before choosing multi-socket solutions, think about your work needs. Consider: expected power use, working temperature, dirt risks, and how much gear moves. For foreign machines, check local rules and safety devices.

Detailed product sheets and help are available to plan panel layouts, pick connector types, and prepare for setup and care. Extra parts like protective caps and cable holders can customize setups.

Clear talk between suppliers, electric teams, and site workers prevents mistakes and meets safety needs. With good planning and regular checks, multi-socket panels using high current plugs and sockets keep tough sites running well.