Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

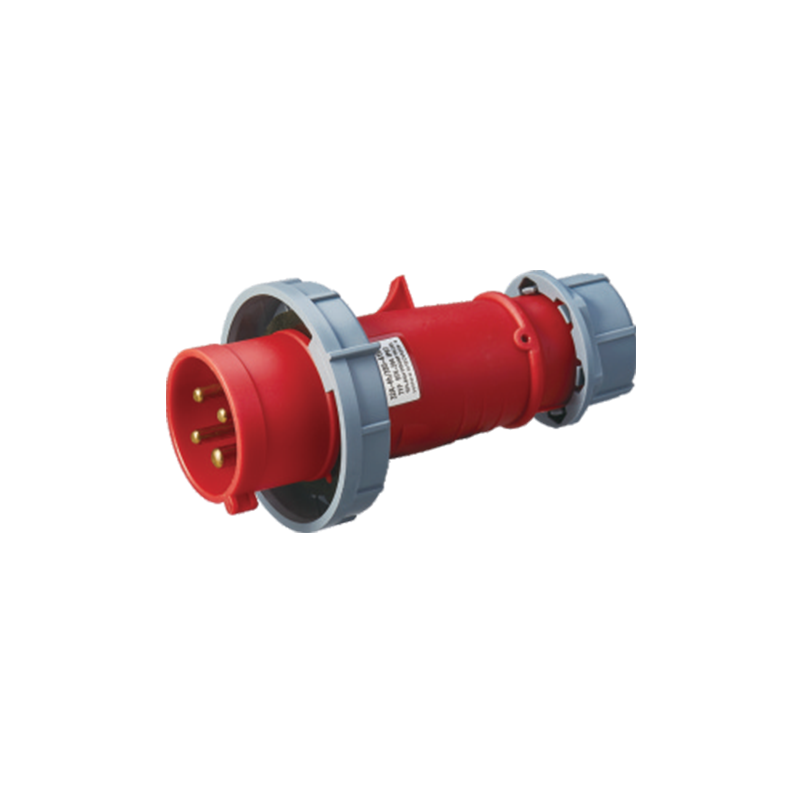

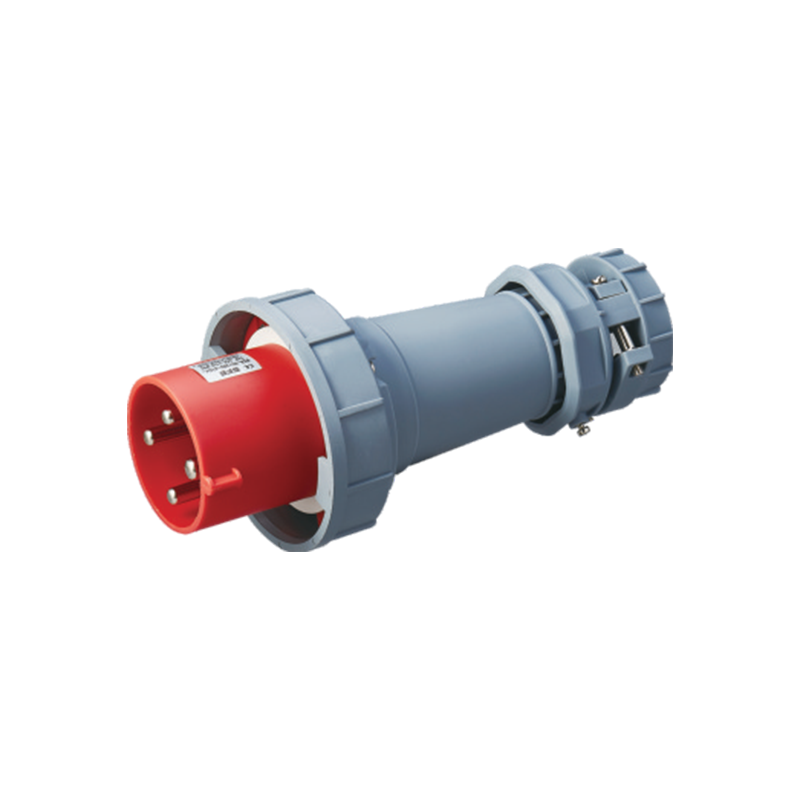

Many workshops and production sites need stable power connections. An Industrial Connector used with a 3-Pin Plug Socket is often a good choice for this. Heavy-duty equipment needs reliable power delivery, safe contacts, and parts that can handle daily use.

Places Suitable for Heavy-Duty Loads

Heavy-duty machines are different. Some run all the time. Others work in short bursts with high power peaks. A 3-Pin Plug Socket is good for equipment that needs stable current, not complex multi-phase power. Examples are machines with a single-phase motor, fixed-speed tools, and portable units that need a good ground wire. The socket has three clear terminals: live, neutral, and earth. It supports machines that need balanced current without a multi-pin connection.

Workshops using drills, air compressors, small cutters, and polishers often use this setup. These tools usually draw power within the socket's safe range. This avoids strain on the connection. Places with regular power cycles also use it. It keeps installation simple and safe.

Modular Equipment on Manufacturing Lines

Many small or medium production lines use separate work stations. Machines like cutting benches, labelers, small mixers, and testers run independently. These machines work well with a 3-Pin Plug Socket. They do not need multi-phase power for changing speeds or torque control.

A modular setup allows quick disconnection. Workers can move a unit for cleaning or switch stations without opening complex panels. When equipment layout changes often, this socket is practical. It keeps things flexible and safe. An Industrial Connector in the system adds resistance to wear, vibration, and temperature changes common in factories.

Construction Sites Using Portable Heavy Tools

Construction sites have changing power needs. Heavy tools like portable cutters, electric breakers, and mixers need a stable power supply. They also must be easy to move. A 3-Pin Plug Socket is often used on temporary boards or portable power boxes. It provides grounded operation and lowers electrical risks during movement.

These sites have dust, moisture, and changing temperatures. Using the socket with a strong Industrial Connector made for tough conditions keeps the connection stable. Tools are plugged and unplugged often. When workers move between floors or areas, a simple grounded single-phase system helps prevent work stoppages.

Service Workshops for Large Appliances

Repair shops for washers, pumps, and motor-driven units often prefer 3-pin sockets. Many of these appliances are made for single-phase power. Their test cycles fit the socket's power level. Technicians plug and unplug many units during checks. A simple, grounded socket design reduces problems and speeds up setup.

Workshops that need controlled testing avoid complicated interfaces. A 3-Pin Plug Socket meets daily needs when used with an Industrial Connector. This stops loose contacts and ensures steady power flow. It helps technicians doing repeated tests or long trial runs.

Agricultural Facilities with Medium-Power Machines

Farms and processing rooms use heavy-duty tools like feed grinders, water pumps, and small conveyors. Some big farm machines need multi-phase power. But many medium-power devices work fine with single-phase power from a 3-pin socket.

These places need equipment that starts quickly without complex wiring. The environment has dust, humidity, and vibration. Industrial Connectors add strength and stability to the power path. Seasonal use makes quick disconnection useful when storing or moving machines.

Small Industrial Spaces with Basic Power Systems

Not all work areas have large power distribution. Many small workshops use simple electrical setups. Upgrading to multi-phase power may not be needed or possible. Here, a 3-Pin Plug Socket gives a grounded, organized way to power heavy-duty tools within its range.

Workers in woodshops, repair rooms, and metalworking areas see their machines run better with consistent connectors. They are better than common household outlets. Using an Industrial Connector with good protection keeps performance steady. This is true even with dust, oil, or metal chips in the workspace.

Temporary Setups and Mobile Units

Some work uses temporary setups. These include show booths, mobile repair trailers, field testing units, and remote project stations. They need a power connection that is safe, portable, and strong. It should not need complex installation.

A 3-Pin Plug Socket is often chosen. It can power equipment like portable compressors, demo machines, or on-site tools. Connecting it through an industrial-grade system keeps cables secure during transport and reconnection.

Mobile repair units also like the simple format. Workers use diagnostic devices or small repair tools. These only need stable single-phase power. The socket's ground terminal is helpful in new places where grounding may be different.