Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

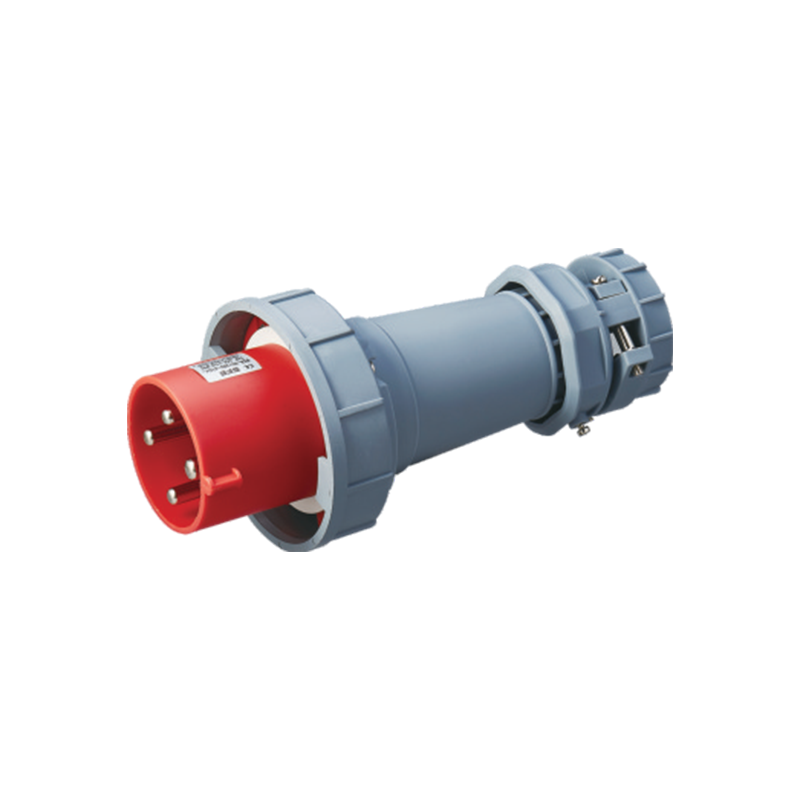

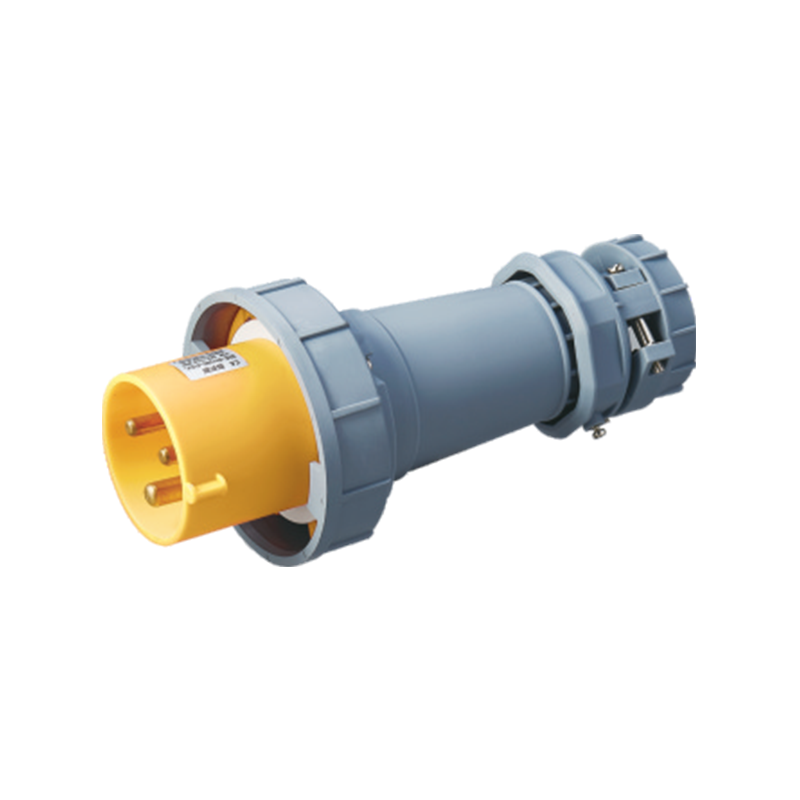

People using portable workstations need power setups that stay reliable. The equipment moves, changes, and is shared between teams. An Industrial Connector used with a 3-Pin Plug Socket is common for mobile benches and temporary work areas. This setup powers tools that must adapt to different jobs. Knowing how the 3-pin design helps allows users to create power systems that work well every day.

Giving Stable Grounding for Moving Stations

Portable workstations often have metal frames, wheels, or adjustable legs. When tools and devices move, grounding is key for safe and steady power. A 3-pin socket has a special ground wire. This keeps electricity stable if the power load changes.

Workstations often switch between tools, test gear, and measuring devices. A stable ground reduces problems from sudden current changes. Industrial Connectors used with these sockets keep contact pressure even. This is helpful when carts or benches move many times a day. Users get a power setup that handles changing needs. It works without complicated changes.

Handling Repeated Use in Shared Spaces

Portable workstations are often used by many people. This happens in workshops, repair shops, or flexible production lines. In one day, tools might be connected and disconnected many times. A 3-pin plug shape helps guide it into the socket correctly. This makes repeated connections easy.

Industrial Connectors made for heavy use have strong contact surfaces and tough housings. Together with the 3-pin design, this reduces wear on the connection points. It also lowers the chance of a bad connection. In places where tools are shared or moved between stations, easy connecting saves time. It stops small mistakes that could break the work flow.

Making Setup Fast in Temporary Spots

Temporary workstations are built quickly. They are used for short projects, prototypes, or field repairs. A 3-Pin Plug Socket makes setup faster. The ground pin acts as a physical guide. Users see the correct direction right away. They can connect devices without a close inspection.

Industrial Connectors help with this. They have secure locks or guide features that match the socket well. When workers move between different workstations, easy alignment cuts confusion. It keeps setup time short. This is very useful on job sites where light is poor or conditions keep changing.

Powering Medium-Duty Portable Tools

Many portable workstations run medium-duty tools. These include drills, grinders, inspection devices, label printers, soldering irons, and work lights. These tools do not need multi-pin connectors or very high-power lines. They need a steady single-circuit power supply.

A 3-pin grounded setup meets this need. It gives a balanced contact surface for medium loads. Paired with an Industrial Connector rated for daily use, the setup supports these tools well. It is not overly complex. Portable stations work better with simple layouts. These layouts still meet safety and performance needs.

Improving Safety During Movement and Shaking

Portable workstations are rolled between rooms. They move over uneven floors or sit near vibrating machinery. This movement can pull on cables and connectors. A 3-pin layout helps keep the connection steady. Its shape naturally resists twisting and coming loose.

Industrial Connectors add to this. They use fixed locks or tight housings that secure both sides of the connection. When a workstation is pulled to a new place, these features help. They reduce stops caused by cable pulling. People who move equipment all day like connections that stay put. They do not want to check them constantly.

Working in Different Indoor and Outdoor Areas

Portable workstations are used in warehouses, garages, under shelters, or near dusty production lines. Many 3-pin sockets have insulated housings or protective covers. These help keep dirt and moisture out. Paired with a strong Industrial Connector, the combination can handle everyday conditions.

This does not replace special waterproof systems. But it is good for situations that need some protection without special connectors. For example, technicians doing checks near doorways or loading areas use this setup. It handles normal conditions without extra changes.

Organizing Cables in Changing Work Areas

Cables can tangle or get strained when workstations move often. A 3-pin plug helps with cable routing. The cable direction is predictable and easy to manage. Industrial Connectors often have reinforced backs or shaped housings. These control the cable path during movement.

For portable setups that relocate many times a day, simple cable routing is key. It reduces accidental strain. Workers can change their bench layout without changing special power lines. This practical benefit helps keep the work area clean and useful.

Helping Training Centers and Shared Learning Spaces

Schools and training centers use portable workstations for lessons and tests. A 3-Pin Plug Socket is good here. Trainees can see how it works with little instruction. This simplicity reduces user error, especially for beginners.

Industrial Connectors used with these sockets add extra durability. Many students handle the equipment. The connectors also keep the connection consistent when the workstation is moved or changed. Teaching places need equipment that works predictably. It should not have unneeded technical difficulty.