Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

Power distribution on construction sites is often hard. Temporary layouts, frequent equipment movement, exposure to dust and water, and changing load demands all put pressure on electrical systems. So, industrial plugs and sockets are very important. They keep power stable and support safe work. They are not simple connectors. They are made to solve the problems in tough work places.

Unlike fixed indoor systems, construction sites need power connections that can be put together, changed, and taken apart many times. They must stay safe. Choosing and using industrial plugs and industrial sockets the right way directly affects the power for tools, machines, and temporary buildings during the project.

Power Demands and Environmental Conditions on Construction Sites

Construction sites change all the time. Electrical equipment may be moved many times in one day. Cables face vibration, impact, and weather. Dust from concrete, rain, and changing temperatures all affect connections.

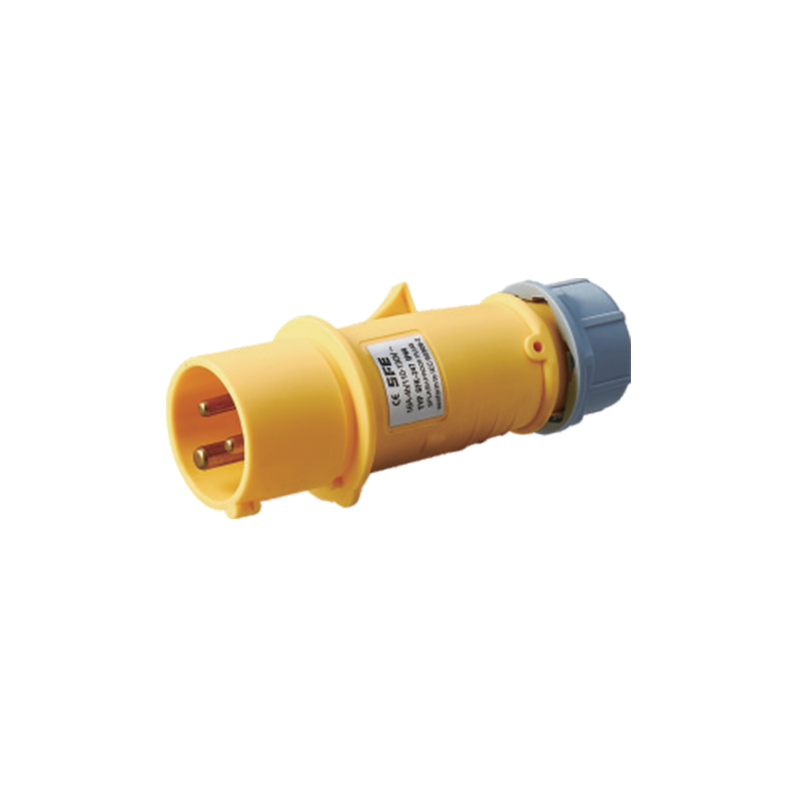

Industrial plugs and sockets work in these conditions because they have strong housings and standard contact parts. Materials like Nylon PA66 are common. They stay strong and keep their shape with heat, water, or chemicals. This helps connectors keep good contact after many uses. So, power is less likely to cut out from loose or bent parts.

Structural Design and Its Role in Power Continuity

Industrial connectors are different from ordinary ones in their design. Industrial sockets usually have strong shells, clear contact pins, and locking parts. These stop accidental unplugging. On a construction site, cables can be pulled or equipment moved. This design helps keep electrical contact steady.

There are different socket types, like concealed direct, concealed inclined, surface mount sockets, and connectors. Workers can choose based on needs. Concealed designs protect wiring inside boxes. Surface-mounted sockets are good for temporary power points that must be easy to see and reach. Inclined designs help with cable routing in tight spaces. This reduces stress on cables and connectors.

Protection Against Dust and Water

Construction sites are not clean. Dust and water often cause electrical problems. So, industrial plugs and sockets have seals to keep out dirt and water. Gaskets, tight covers, and good design all help.

This protection does not mean connectors can be ignored. But it helps keep power on when the environment is bad. For instance, outdoor equipment in rain needs connectors that work safely even when wet. This means fewer work stoppages from power cuts.

Standardization and Compatibility Across Equipment

Construction projects use equipment from many suppliers. They may have different voltage and current needs. Industrial plugs and sockets follow international rules like IEC60309. They also follow national rules like GB11918 and GB11919. This helps with compatibility.

Standard sizes, pin layouts, and colors let workers quickly find the right connection. This lowers the chance of wrong connections that can break equipment or cause danger. Also, standardization makes maintenance and replacement easier. Workers can find parts without changing the whole power system.

Ease of Installation and On-Site Changes

Saving time is important on construction sites. Industrial plugs and sockets are made for easy installation. Electricians can put them together or replace them with common tools. Clear markings and strong clamps make cable connections secure, even in temporary setups.

When power needs change during the project, connectors can be moved or changed without a lot of new wiring. This flexibility helps in different project stages. Different site areas need power at different times.