Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

Power connections used in tough workplaces often face rain, splashing water, dust, and debris. In these conditions, picking the right industrial plugs and industrial sockets is a very practical choice. It is not just a technical detail. These parts directly affect how safe and steady the power is for equipment used outside or in dirty industrial places. Knowing what to look for helps users avoid common problems from water, dirt, and early wear.

Do not just look at performance claims. It is better to see how the design, materials, and standards fit the real site conditions. This way, you can make good choices when power connections must work with water and dust around.

Understanding the Nature of Water and Dust Exposure

You should think about what kind of exposure will happen. Some sites have only occasional rain or cleaning sprays. Other sites have constant dust from cement, soil, or metal work. Water can mean splashes, drips, or even short dips. Dust can be fine powder or large pieces.

Industrial connectors for these places have protection built in. But, not all products are made for the same level of exposure. You should decide: will the connectors be used inside with dusty air, outside in the weather, or near water? This thinking helps find the right options.

Material Selection and Environmental Resistance

The material of the plug and socket body is very important. It decides how well it handles the environment. Engineering plastics like Nylon PA66 are common for industrial uses. They keep their shape when temperatures change. They also resist damage from moisture.

This material also resists many oils and chemicals found on industrial sites. No material is perfect for all conditions. But, choosing connectors made from strong, tolerant materials lowers the chance of cracks, swelling, or parts getting loose over time. These material traits help keep the contacts lined up right. This is needed for stable power transfer.

Sealing Design and Protection Against Ingress

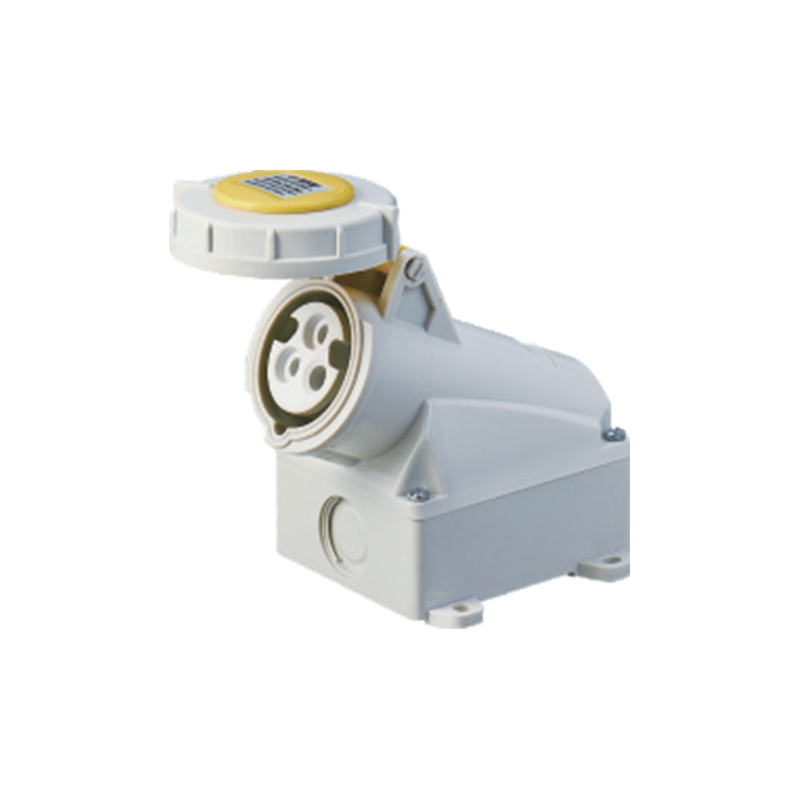

Water and dust usually get into connectors through gaps. These gaps are where parts connect, where the cable goes in, or where covers are left open. Industrial plugs and sockets for exposed places usually have seals like gaskets or tight fits. These parts limit what gets inside.

Connectors with good locking or joining mechanisms help press the seals together properly. This design point lowers the chance of water or dust reaching the electrical contacts during normal use.

Also, think about how people use the connectors. It also works when socket covers are closed when not in use. Choosing designs that make the right habits easy is a big help on busy sites.

IP Ratings and What They Indicate

Ingress Protection (IP) ratings give a standard way to know how well electrical equipment keeps out solids and liquids. For industrial plugs and sockets, IP ratings let users compare products based on tested protection levels. They do not need to guess.

The number in an IP rating is for protection against solids like dust. The second number is for resistance to water. Higher numbers mean more protection in the tests. When picking connectors for water and dust, match the IP rating to the real place. Do not choose a very high rating if you do not need it.

Knowing IP ratings lets users pick connectors that fit their situation. Examples are rain, splashing water, or dusty air. You do not need to over-specify.

Structural Design and Connection Stability

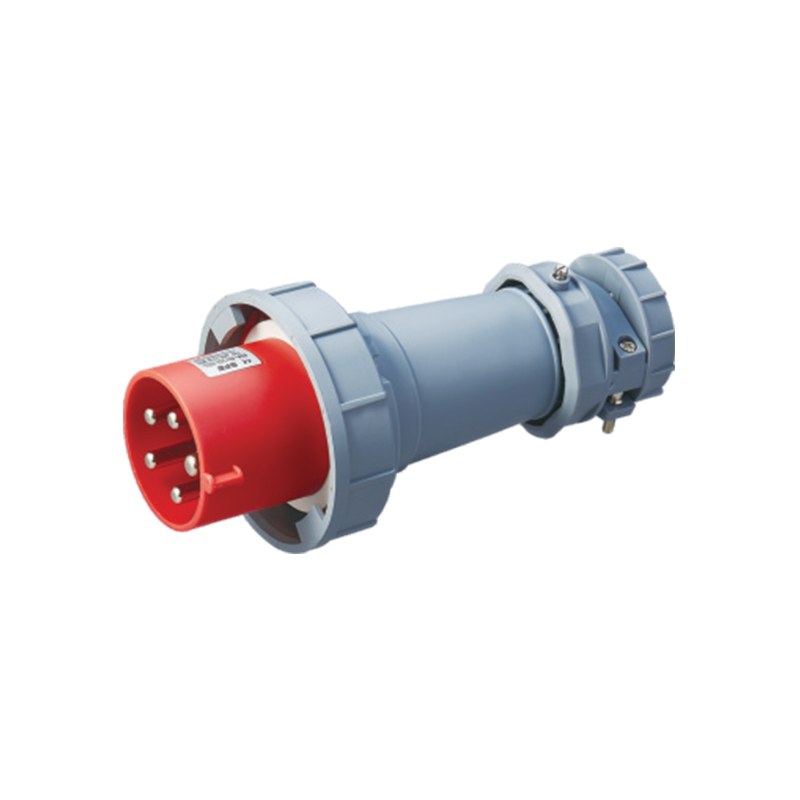

In places with dust and moisture, a stable connection is part of the protection. A loose connection can break the seals and let dirt in. So, industrial plugs are made with strong pins and bodies. They stay aligned even with vibration or cable pulls.

Locking features, if the plug has them, help keep the connection steady during use. This is very important on sites where cables are moved often. Stable connections give steady electrical contact. They also help the protective seals work as they should.

Cable Entry and Strain Relief Considerations

Water and dust can also get in where the cable enters the plug. This happens if the cable is not held well. Industrial plugs for exposed places usually have cable clamps or glands. These parts hold the cable jacket tightly. This reduces movement where the wires end. It helps keep the inside seals intact.

When you choose industrial plugs, check if the cable size fits the plug’s range. A proper fit makes sure the strain relief works. It does not leave gaps for dirt or water.

Compatibility with Industrial Sockets and Systems

You cannot choose industrial plugs alone. They must work with the right industrial sockets. This is needed to keep the protection level. Connectors made to known standards make sure plugs and sockets fit together right. This keeps the seals and contact alignment good.

Standards like IEC60309, EN60309, and CEE17 set the sizes, pin patterns, and electrical ratings. National standards like GB11918 and GB11919 do this for specific markets. Using standard parts helps avoid bad connections. Bad connections can ruin the protection against water and dust.