Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

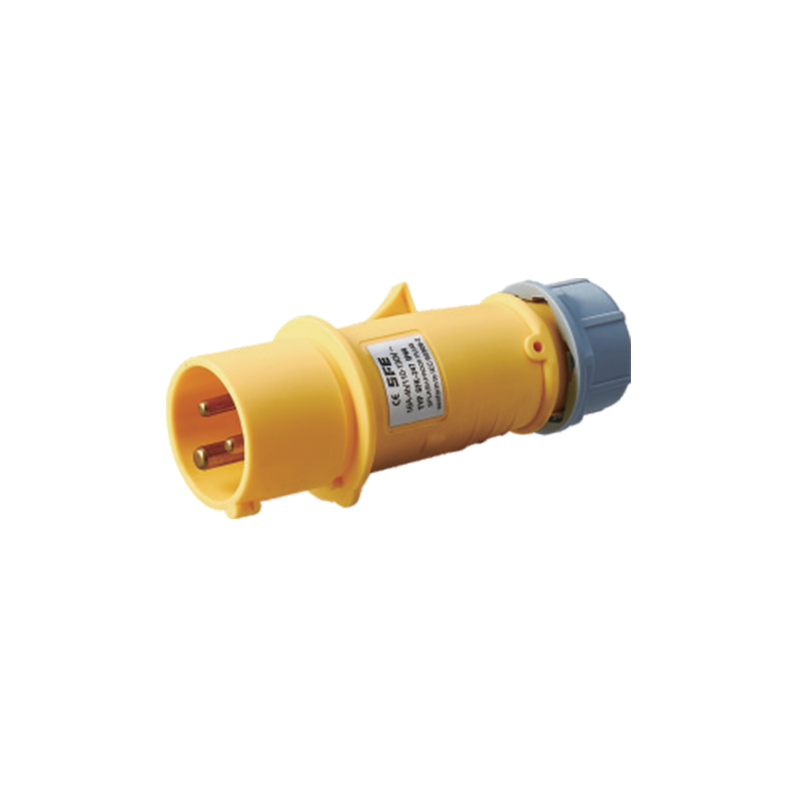

Electrical work on industrial sites often happens under time pressure. Conditions can also change. Before starting any wiring, careful preparation helps avoid later fixes. These fixes can stop work or cause safety problems. When you choose industrial plugs and industrial sockets for on-site use, do not guess how to install them. Follow practical checks. These parts connect power systems to equipment. Their placement and setup need careful attention.

Do not treat installation as a normal job. This helps the system start well and run smoothly later. The points below are for common conditions. You find these on construction sites, in factories, and in outdoor industrial areas.

Confirming Power Requirements and Electrical Ratings

Check the electrical needs of the equipment. Look at the voltage, current, and frequency. These must match the socket and the plug. Wrong ratings can cause unsafe operation or damage.

Industrial sockets come in different types for standard electrical needs. Check the nameplate on your machinery. Check your site’s power supply. This makes sure the connectors match the real operating conditions. This step also helps follow electrical rules. It makes it less likely you will need to redo the work later.

Evaluating Environmental Conditions on Site

Think about the environment. Dust, moisture, temperature changes, and chemicals all matter. They affect which connectors you pick and where you put them. Before installation, decide if the socket will be indoors, outdoors, or in a partly closed area.

Sites with water from rain, cleaning, or processes need sockets with good seals. Dusty places need enclosed designs. This stops particles from building up on the contacts. Understand these conditions. Then you can place sockets to limit unnecessary exposure.

Selecting Suitable Mounting Methods

Industrial sockets come in different mounting styles. You can surface-mount them, panel-mount them, or use concealed designs (direct or inclined). Each style fits different site layouts and uses.

Before installing, think about cable routes and how equipment will connect.Surface-mounted sockets are good for temporary or easy-to-reach power points. Concealed installations are common in distribution panels or on fixed machines. Inclined designs help in tight spaces. They reduce strain on the connector and cable.

Checking Structural Support and Installation Surfaces

The surface where you install the socket must be strong enough. Vibration, impacts, and cable weight can make the installation loose over time. Before mounting, check that walls, panels, or frames can hold the socket firmly. They should not bend or break.

Uneven or soft surfaces might need extra brackets or support. This is very important on construction sites and movable setups. Temporary structures can shift. Good support keeps plugs and sockets lined up. This ensures steady electrical contact.

Planning Cable Entry and Strain Relief

Do not forget cable management. Industrial sockets need proper cable entry and strain relief. This keeps internal connections and seals working. Before installation, check the cable diameter. Make sure it fits the socket’s range.

Good strain relief stops movement where the wires connect. This keeps the electrical contact secure. It also reduces wear over time. Plan the cable path ahead. Avoid sharp bends or pulling tension. This helps long-term stability.

Verifying Protection Against Dust and Moisture

Sockets in wet or dusty places need proper protection. Check the ingress protection (IP) features before installation. IP ratings tell you the level of protection against solids and liquids. But they only work if installed correctly.

Before mounting, check the gaskets, covers, and sealing surfaces. Make sure they are not damaged and are clean. Bad installation can ruin these features. Then dirt and water can get in. Paying attention to these details makes sure the environmental protection works as intended.

Assessing Accessibility for Operation and Maintenance

Install sockets where people can reach them safely. People need to connect, disconnect, and inspect them. Before installation, think about daily use.

Do not put sockets too close to moving machinery, hot surfaces, or tight corners. This makes them hard to reach or check. Leave enough space. Then plugs can be put in fully, and covers can close when not in use. Maintenance teams also need to see the socket easily. They should not have to take apart other equipment to check it.

Reviewing Safety and Isolation Requirements

Before installing, check the site’s safety rules. Local rules may need isolation switches, lockout devices, or special labels near power outlets.

Industrial sockets are not isolation devices themselves. But where you put them in the electrical system affects safety. It affects how safely equipment can be connected or serviced. Plan socket installation along with circuit protection and isolation. This supports safe work practices on site.