Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

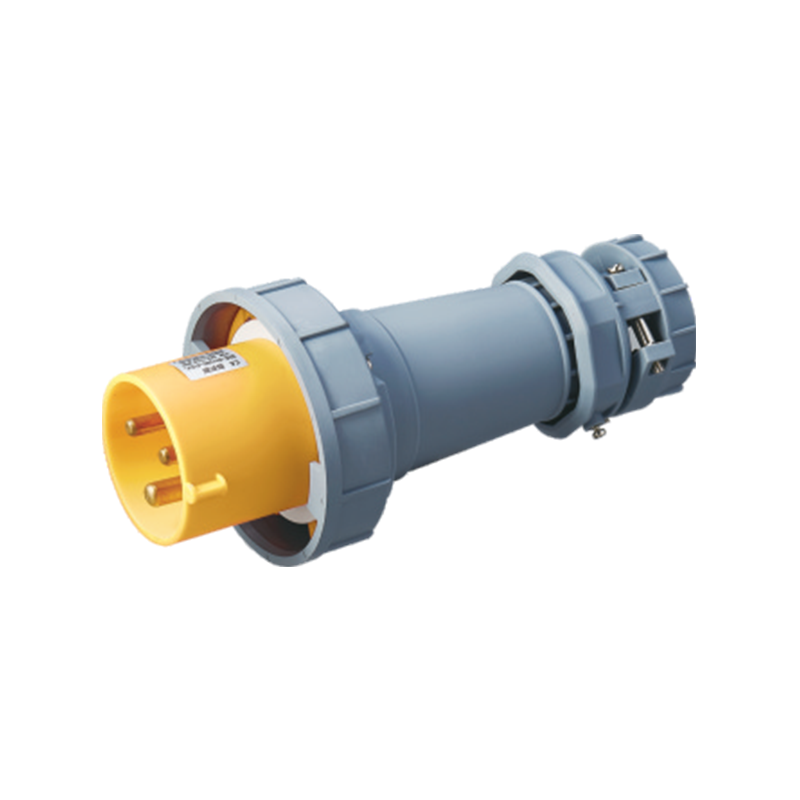

People often look at the outside of an electrical connector. But the inside parts are more important for long-term safety and performance. When a Waterproof Industrial Plug is made for 230v use, its inside must balance electrical needs, physical strength, and protection from the environment. So, a 230v Industrial Plug is defined more by how its inside parts work together every day. This happens under conditions like changing electrical load, vibration, and wetness.

Knowing these inside features helps users see if a plug design is good for their specific industrial place. It is better than just using general labels.

The Contact Setup and How Current Flows

The contact system is the heart of a 230v industrial plug. The layout of the live, neutral, and earth contacts decides how electricity flows. It also decides how the electrical load is shared.

The metal contacts inside are shaped to stay firmly connected when the plug is fully pushed into a socket. This steady connection stops changes in contact resistance. These changes can happen from vibration or from plugging and unplugging many times. In waterproof industrial plugs, the contacts are often placed deeper inside the housing. This creates space between the metal parts and the outside world.

The path for the current is made to be straight and simple. Sharp bends or extra turns inside the plug body are avoided. These could create spots of higher resistance and heat buildup over time.

Insulation Barriers and Space Inside

Insulation is not just the outer shell. Inside insulation barriers are a key part of a 230v industrial plug structure. These barriers keep the conductive parts apart from each other. They also keep them apart from the housing.

The space between contacts follows set rules for electrical clearance. This space helps keep electrical behavior stable when the air is humid. It also lowers the chance of unwanted electrical paths forming from dust or moisture.

Some inside insulation parts are molded as one piece with the housing. Others are separate pieces put inside. Both ways try to keep the same separation, even if the plug gets physical stress or temperature changes.

Sealing Parts Inside the Plug Body

People often talk about outside seals. But inside sealing parts also help build a waterproof industrial plug. These seals limit how far moisture can go if it gets past the outer layers.

Inside gaskets or walls may be placed between the area holding the contacts and the area where the cable is attached. This design helps protect sensitive parts from the environment. This environmental exposure can come in where the cable enters.

These inside parts do not make a completely airtight space. Instead, they control moisture movement. They make it less likely that condensation will reach the metal conducting parts.

How the Cable is Held Inside

The inside area where the cable ends is very important. It defines how firmly the wires are held. In a 230v industrial plug, this area must keep a steady electrical contact. It also must work with different cable types and wire sizes.

Common methods to hold the wires include screw terminals or clamping parts. These are made to press evenly on the wire. This reduces the risk of loosening from heat cycles or vibration.

In waterproof industrial plugs, this cable chamber is often divided from the outer housing by an insulating wall. This separation helps with electrical safety and managing the environment.

How Strain Relief is Built Inside

Strain relief is often seen as an outside part. But how it is built inside is just as important. Inside the plug, strain relief parts are made to pull mechanical forces away from the electrical terminals.

Inside supports may hold the cable jacket tightly. They may also work with the outer cable gland to spread pulling forces over a bigger area. This lowers the stress on the connection points. Without this, the wires could get damaged or become loose over time.

For portable equipment using 230v industrial plugs, this inside support structure helps keep connections stable. This is true even when the equipment is moved often.

The Earth Connection Setup

The earth connection inside a 230v industrial plug has a special design. It is made to connect before the live contacts when you plug it in. It is made to disconnect after the live contacts when you unplug it. This order happens because of the contact length and position. It does not need electronic controls.

Inside, the earth wire is usually routed along a set path. This path reduces its exposure to physical stress. Its connection point is often made stronger. This keeps it working, even if other parts wear down.

This inside setup is about practical safety. It is not just a performance claim.

Managing Heat Inside

Heat inside a plug comes from contact resistance, current flow, and the housing design. The inside features of a waterproof industrial plug are shaped to handle heat spread. They do not remove all heat.

The materials used for inside supports and insulation are chosen because they stay stable when hot. Air gaps and space inside can also change how heat escapes from the plug body.