Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

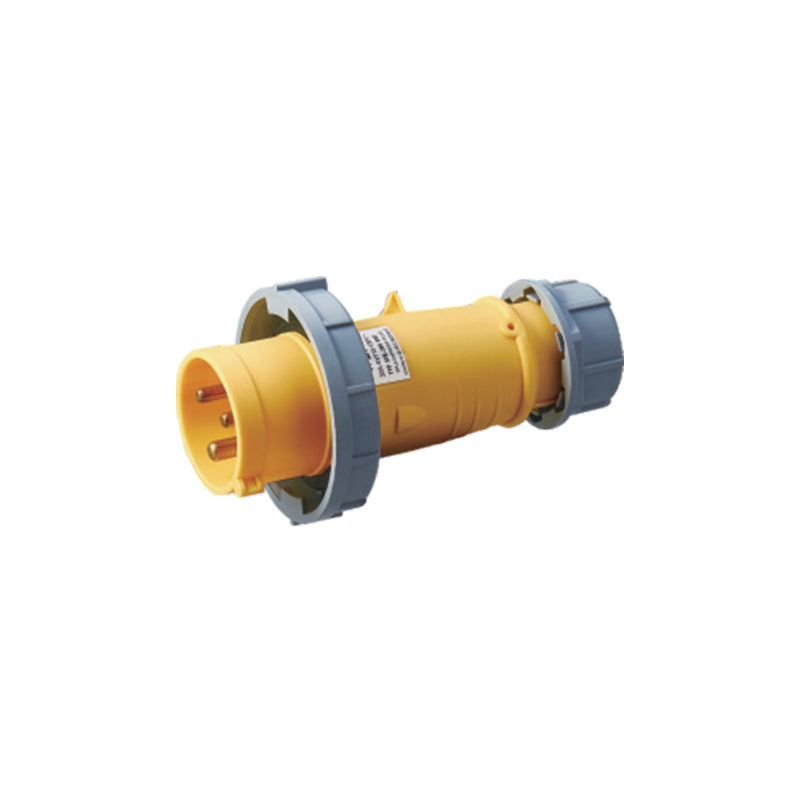

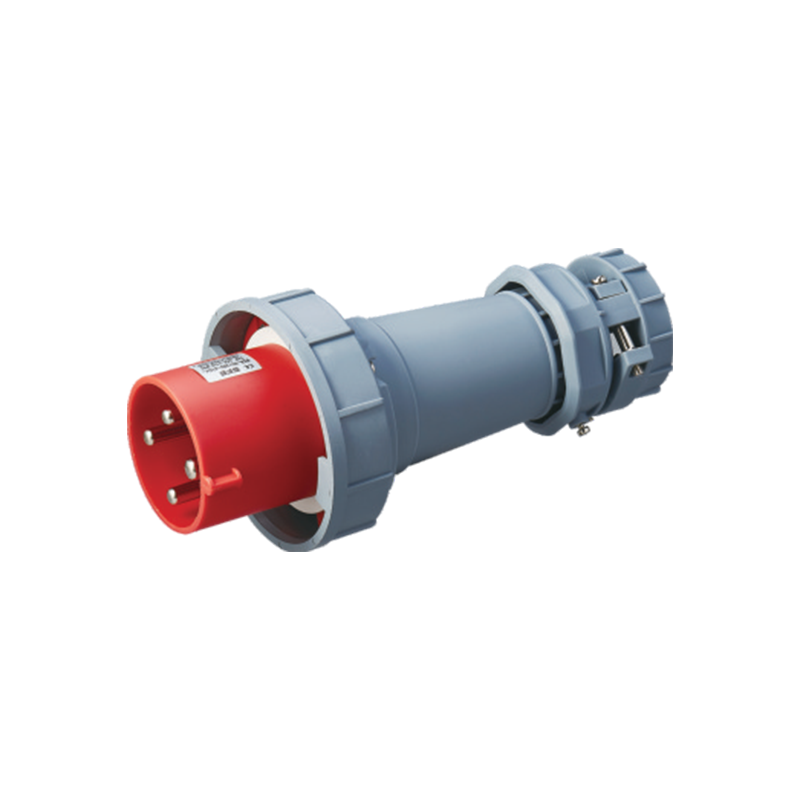

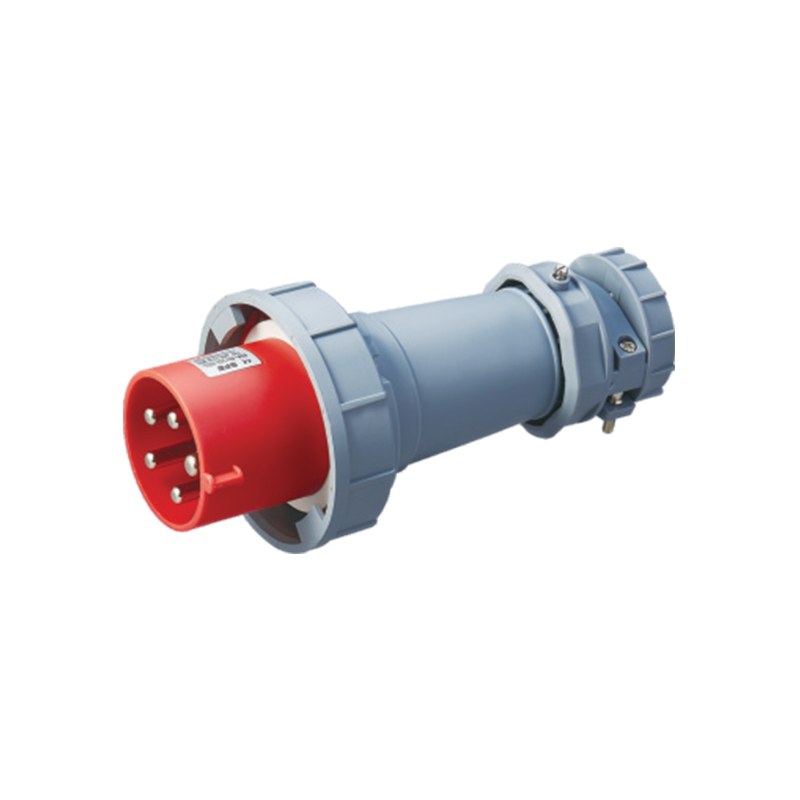

Connection problems in industrial electrical systems do not usually happen suddenly. They often come from slow damage caused by water, dust, shaking, and being used many times. When power connections are used in places with these conditions, the design of the plug itself can change how often problems happen. The Waterproof Industrial Plug and the 230v Industrial Plug are often chosen where steady power is needed, even when the environment is wet or dirty. Their design features are directly linked to having fewer connection issues.

Connection problems usually start from two things working together: the environment and physical stress. Knowing how waterproof industrial plugs handle these things helps people choose, install, and care for them correctly.

Knowing Why Connections Often Fail

It is good to know the common reasons for plug failure. Water getting inside is a major cause, but other things usually happen too.

Water in a connector can lower insulation resistance. This can let small leakage currents form. Over time, this can make the voltage unsteady and affect machines. Also, vibration and plugging/unplugging the connector many times can loosen the metal contacts or damage the seals. Dust and small particles can also interfere with the contact surfaces, especially if the air is humid.

For a 230v industrial plug, these problems are serious. This voltage is used for many industrial tools, machines, and support systems. Any unreliability at the plug can affect how equipment runs and how often it needs repair.

How Waterproof Design Stops Moisture Problems

A waterproof industrial plug works well because of several design parts working together. These parts limit water entry. By controlling moisture, the plug tackles a main cause of failure.

Seals are built in at several important points. These include where the plug meets the socket and where the cable goes in. These seals block common ways for moisture to enter, like from splashing, condensation, or creeping along the cable. When water is kept away from the metal conducting parts, there is less chance of corrosion and insulation damage.

This method does not remove all environmental danger. But it helps keep electrical performance stable for a longer time. This is especially useful outdoors or in places that get washed down.

Keeping Good Contact Pressure and Steady Power

Connection problems are often linked to poor contact pressure. If the metal contacts become loose or misaligned, electrical resistance goes up. This can cause local heating or power that cuts in and out.

Waterproof industrial plugs often use contact designs that stay firmly connected. This happens even with vibration or temperature changes. By keeping the contacts in the right place, the plug reduces tiny movements that cause wear.

In a 230v industrial plug, steady contact pressure also keeps the electrical behavior predictable. When resistance stays normal, there is less risk of breakers tripping for no reason, voltage changing, or equipment shutting off unexpectedly.

Strong Housing and Physical Protection

The outer shell of a waterproof industrial plug helps avoid failures by shielding the inside parts from damage. Industrial places often have risks like impacts, cables being pulled, and accidental force during use.

Strong plastic housings are common. They resist bending and cracking even under repeated stress. When the housing keeps its shape, the seals inside stay pressed tight, and the contacts stay aligned.

This strength supports good connection quality for the long term. It makes sure the environmental protection keeps working correctly through normal daily use.

Cable Entry Design and Avoiding Failure

The point where the cable enters the plug is often a source of problems. Without good strain relief and sealing, movement here can loosen the internal wires or let water in.

A waterproof industrial plug usually has a built-in cable gland. This part gives mechanical support and seals at the same time. The design pulls forces along the cable. It does not put all the force directly on the internal screw terminals.

Good cable entry design prevents several problems at once.

- It limits wire movement that can loosen terminal screws.

- It keeps the seal around the cable jacket effective.

- It lowers the risk of the internal wires breaking from fatigue.

For 230v industrial plug setups with portable equipment, this is very important. These plugs are moved and repositioned often.

Separating Conductive Parts Inside the Plug

Another way waterproof industrial plugs reduce failure is by keeping the conductive parts apart inside. Insulating walls and careful spacing are used. This manages both electrical safety and environmental exposure.

By keeping the phase and neutral conductors separate inside the plug body, the design lowers the chance that moisture or dirt could create a bridge between contacts. This separation helps keep electrical performance stable. It helps even if a little moisture gets into the outer areas of the connector.

For people trying to find an intermittent electrical fault, this internal design often explains why waterproof plugs have fewer mysterious problems compared to plugs that are not sealed.