Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

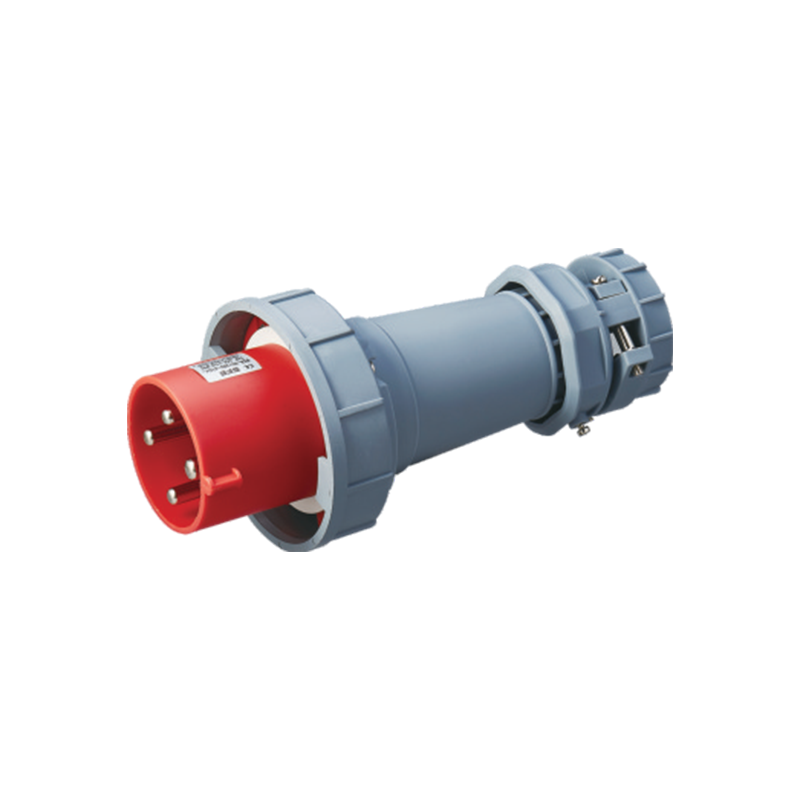

Electrical connections in tough places often face rain, wet air, washdowns, dust, and changing temperatures. In these conditions, keeping water out is a main design goal, not just an extra feature. When we talk about answers for industrial power, the Waterproof Industrial Plug and the 230v Industrial Plug are often mentioned. This is because they solve both electrical needs and protection from the environment. They do not use simple coatings or temporary covers. Instead, they are built from the start to stop water and moisture from entering. This helps keep electrical performance stable every day.

Water getting in is not only about seeing water. Condensation, capillary action, and pressure changes can all let moisture into electrical parts. To know how a waterproof industrial plug handles these risks, we need to look at its build, materials, and how it is used.

Why Stopping Moisture is Important for Industrial Power Connections

In industrial places, electrical plugs are not often in clean, dry rooms. They might be near production lines, outdoor machines, mobile equipment, or temporary power points. Here, moisture can cause several problems.

Water in a plug can lower insulation resistance. This might cause leakage currents or unstable power. Over time, repeated wetness can also cause corrosion at contact points. This increases resistance and heat. Even without clear damage, small amounts of trapped moisture can shorten life and mean more maintenance.

For a 230v industrial plug, these risks are bigger. This is because 230v is common for many types of equipment, like pumps, compressors, lights, and portable tools. So, a waterproof design is not about adding something extra. It is about managing a common environmental problem.

Sealing Structures That Stop Water Entry

A key part of any waterproof industrial plug is its sealing. Many designs do not use just one barrier. They use several sealing points to block different ways moisture can enter.

The place where the plug body meets the cable jacket is usually sealed with a compression gland. This gland tightens around the cable when put together.

The meeting surface between the plug and the socket often has a rubber-like gasket. This gasket presses tight when connected.

Also, inside, there may be barriers between the metal contacts and the outer shell. This stops moisture from spreading if it gets past the outer shell.

These seals work together. They handle both direct water and indirect moisture like humid air or splashes. The goal is not to be completely airtight. It is to limit water entry so much that it does not harm electrical safety.

Housing Materials and Their Job in Moisture Resistance

The housing material of a waterproof industrial plug is very important for moisture control. Common materials are strong plastics and engineered polymers. They are chosen because they keep their shape and soak up very little water.

Unlike metal, these materials do not rust when wet. They also keep their size well when temperatures change. This helps keep the gaskets pressed tight over time. If a housing warps from heat or cold, even a good seal can fail.

For 230v industrial plug uses, material choice must also think about physical stress. Plugs are often connected and disconnected many times. This sometimes happens under load or in bad positions. A stable housing makes sure the sealing parts stay in the right place through all this use.

Contact Design and Moisture Control

Outside seals stop a lot of water. But the design of the metal contacts inside also helps resist moisture. Contacts in waterproof industrial plugs are usually shaped to have less exposed area. This limits tiny paths where moisture could creep in.

Some designs put contacts deeper inside the plug body. So, even if the outside gets wet, the metal parts stay protected. Others use insulating walls or sleeves to separate the different wires (like phase, neutral). This lowers the chance of moisture creating a bridge between conductors.

For a 230v industrial plug, keeping steady contact pressure is key. Steady pressure reduces tiny gaps where moisture could gather. This is extra important in places with vibration or movement.

Cable Entry and Strain Relief

A common place for moisture to enter is where the cable goes into the plug. A waterproof industrial plug fixes this with built-in strain relief and sealing parts.

The cable gland has two jobs. It holds the cable firmly to reduce stress on the inside connections. It squeezes the cable sheath to stop moisture from entering. How well this works depends on using a cable with the right thickness and tightening the gland correctly.

If the cable is too thin or the gland is not tightened evenly, moisture protection gets worse. This shows that being waterproof is not only about design. It is also about how it is installed.

Environmental Ratings and What They Mean in Practice

Waterproof industrial plugs often have IP ratings. These ratings describe how well they keep out solids and water. The rating is a standard reference, but what it means in real life depends on where it is used.

For example, a plug rated against splashing water might be good for indoor workshops that are cleaned sometimes. Outdoor places or areas with washdowns might need a higher rating against water jets or short immersion.

When choosing a 230v industrial plug, it is good to think about the rating in your specific situation. The rating tells you about test conditions, not every real-world possibility.