Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

The electrical socket manufacturing industry is undergoing significant changes due to new regulatory trends that influence production methods, safety standards, and product design. These regulations aim to improve consumer safety, ensure environmental compliance, and address emerging technological needs. As a result, manufacturers of High Current Plugs And Sockets and Combination Socket Boxes must adapt their processes to meet these evolving standards while maintaining product reliability and market competitiveness.

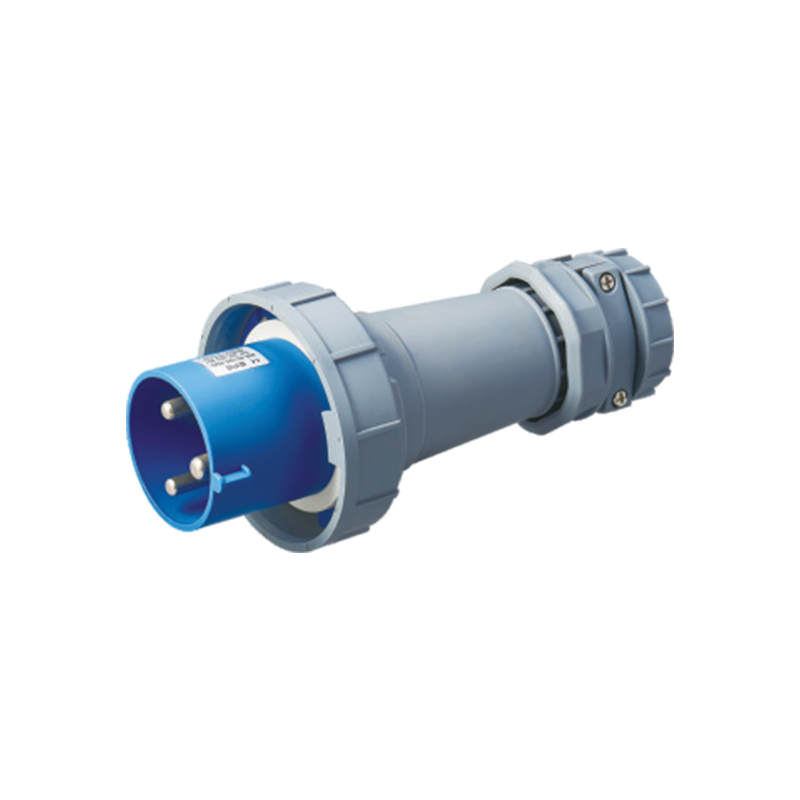

One of the more noticeable regulatory shifts concerns the safety requirements for electrical devices, particularly High Current Plugs And Sockets. Governments and regulatory bodies have introduced stricter testing protocols to reduce risks such as electrical fires, overheating, and electric shocks. Manufacturers now face tighter scrutiny in how they design and test High Current Plugs And Sockets to ensure compliance with these safety mandates. This has led to innovations in insulation materials, contact quality, and thermal resistance features integrated into these products.

At the same time, regulations have expanded to cover Combination Socket Boxes, a critical component in many electrical systems. These devices combine multiple socket types in one unit to serve diverse power needs in residential, commercial, and industrial settings. Regulatory authorities have issued specific guidelines related to the durability, wiring safety, and installation procedures for Combination Socket Boxes. Manufacturers are now required to conduct rigorous quality assurance tests and document compliance before bringing these products to market.

Environmental regulations also play a significant role in reshaping manufacturing practices. The push toward sustainability has led to stricter limits on hazardous substances used in electrical components, including those found in High Current Plugs And Sockets and Combination Socket Boxes. The implementation of directives similar to RoHS (Restriction of Hazardous Substances) compels manufacturers to eliminate or reduce advance, mercury, cadmium, and other harmful materials from their products. This shift demands new sourcing strategies and adjustments in the manufacturing process to achieve compliance without compromising product integrity.

Furthermore, energy efficiency has become a critical focus within regulatory frameworks. Electrical sockets, including High Current Plugs And Sockets, are now subject to standards that encourage lower power loss and improved energy conservation. These standards affect design choices such as contact resistance, material conductivity, and mechanical structure. Combination Socket Boxes also fall under these regulations, requiring manufacturers to optimize internal circuitry and reduce standby power consumption. Such changes not only align with regulatory demands but also respond to consumer expectations for more energy-conscious products.

The rise of smart technology integration is another factor influencing regulatory trends. As High Current Plugs And Sockets and Combination Socket Boxes increasingly incorporate smart features like remote control, energy monitoring, and safety shutoff mechanisms, new certification requirements have emerged. These certifications evaluate electromagnetic compatibility, cybersecurity resilience, and communication protocol standards. Manufacturers must invest in research and development to ensure that their smart-enabled products comply with these additional layers of regulation while maintaining core safety and performance criteria.

Adapting to these new regulatory trends requires a comprehensive approach across the entire manufacturing process. For producers of High Current Plugs And Sockets, this means revisiting material selection, production line automation, and testing procedures. By incorporating advanced testing equipment and automated quality control systems, manufacturers can consistently meet the stringent safety and environmental standards now in place. Similarly, Combination Socket Box production facilities are adopting modular design approaches and enhanced inspection protocols to address regulatory complexity efficiently.

Training and workforce development are also crucial components of compliance. Workers involved in the assembly and inspection of High Current Plugs And Sockets and Combination Socket Boxes need up-to-date knowledge about regulatory requirements and ideal manufacturing practices. Regular training programs ensure that personnel understand the importance of compliance measures and can implement them effectively in daily operations. This commitment helps less errors and reduces the risk of non-compliance penalties.

Supply chain management is another area affected by these regulatory changes. Manufacturers must ensure that all raw materials and components used in High Current Plugs And Sockets and Combination Socket Boxes meet relevant standards before they enter the production line. This requires closer collaboration with suppliers, detailed documentation, and traceability systems to guarantee the origin and quality of materials. Enhanced supply chain transparency not only supports regulatory compliance but also strengthens product quality control.

Overall, the new regulatory trends impacting electrical socket manufacturing processes present both challenges and opportunities. While compliance with safety, environmental, and technological standards can increase production complexity and costs, these regulations also drive innovation and improve product quality. For manufacturers specializing in High Current Plugs And Sockets and Combination Socket Boxes, staying ahead of regulatory developments is essential for maintaining market presence and customer trust.

In conclusion, the electrical socket manufacturing industry must navigate an evolving regulatory landscape that affects every stage of production. The growing emphasis on safety, environmental responsibility, energy efficiency, and smart technology integration requires manufacturers to adapt their processes and products continually. By focusing on compliance with these new standards, companies producing High Current Plugs And Sockets and Combination Socket Boxes can contribute to safer electrical environments and more sustainable practices in the industry.