Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

Construction sites are a fast-changing environment, where safety, reliability and efficiency are always key factors for success. A wide variety of power tools requires a flexible power distribution system. Multi-outlet systems and high-current plugs can meet this need. These electrical components ensure efficient power distribution and help to use electricity safely during construction.

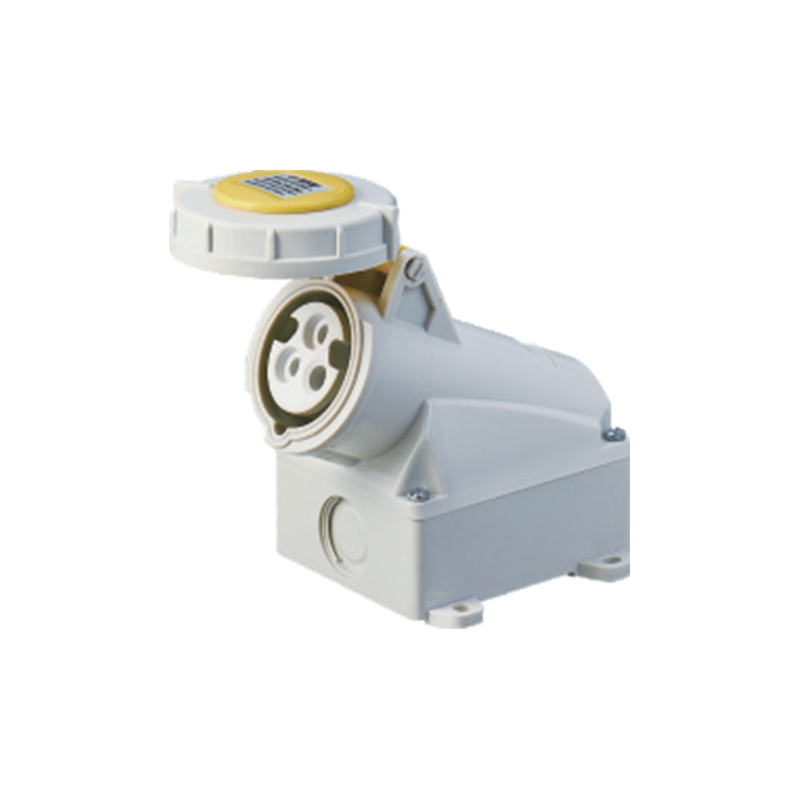

Construction sites often operate multiple power tools at the same time. Drills, welders, cranes and lighting systems all require power. A single power source often cannot meet the demand. Multi-outlet sockets provide a practical solution. These sockets allow multiple devices to be connected from one power source.

Multi-outlet systems distribute power evenly and safely. These sockets are able to effectively manage high-current loads. Multiple tools can be operated without overloading the circuit. This feature is essential on construction sites. Because the power demand on construction sites fluctuates greatly and the power requirements of equipment vary greatly.

Multi-outlet applications can maintain a stable on-site workflow and effectively centralize power distribution. This approach replaces multiple extension cords and avoids the need to connect tools directly to the main power source. Centralized power distribution significantly reduces clutter. It significantly reduces the risk of accidents.

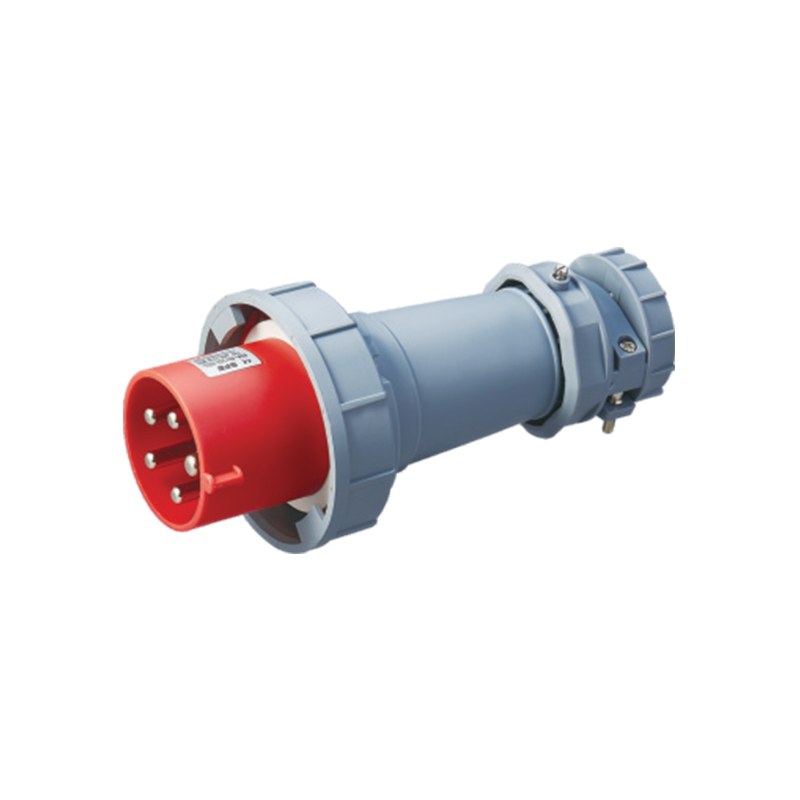

High-current plugs and sockets withstand high current loads. Many industrial tools require higher current levels. Heavy-duty connectors deliver this power safely. These components prevent the risk of overheating or failure.

Construction sites use high-current plugs to connect large machinery. Concrete mixers, compressors, and welding machines all require them. These components are able to withstand higher electrical stresses, providing a reliable and safe connection. This safety reduces the possibility of electrical failure.

Combining a multi-socket system with a high-current plug allows multiple devices to be powered safely. These connections provide the necessary durability to successfully withstand harsh site environments. The electrical system is able to continuously handle high power loads, reducing the possibility of interruptions.

Durability is critical for electrical components on construction sites. Multi-socket systems and high-current plugs are subject to harsh environmental conditions. Dust, moisture, and frequent use are common conditions. Reinforced plastics and weather-resistant coatings ensure their functionality. These materials maintain their performance even in harsh environments.

Safety is another important factor. Construction sites are high-risk areas. Electrical accidents can have serious consequences. Multi-sockets have a variety of protection features. Guards, grounding and overload protection prevent hazards. High-current plugs reduce the risk of sparks or electrical fires and provide additional safety for workers.

Multi-socket systems are versatile. Temporary power stations can use them effectively to provide connections for multiple workers or equipment. Portable multi-socket units enable mobile power solutions, and this flexibility helps workers move between different sites.

High-current plugs meet high power demands. Large construction machinery relies on them. Lighting systems for night operations use these plugs. Heavy tools that require higher energy input also need them.

Large projects integrate multi-socket systems with overall site power. These systems are connected to generators or temporary power distribution units. Generators supply power to the entire site. Uniform power distribution reduces downtime and makes operations smoother.

Multi-sockets combined with high-current plugs facilitate power access. Workers can safely connect tools from various locations on the site. Cutting, drilling or measuring tools can all be easily plugged in. Large lifting and excavation equipment is reliably powered.

Multi-socket applications reduce operational delays. Multiple tools and machines can be powered simultaneously. Workers no longer have to wait for free sockets or extension cords. Productivity is significantly increased. Interruptions during critical construction phases are reduced.

High-current plugs ensure continuous power. Equipment demands sometimes exceed standard levels. These components reliably handle high loads. Circuit breaker trips or power outages are significantly reduced. Work proceeds smoothly and unnecessary delays are avoided.

Multi-socket applications and high-current plugs ensure efficient construction site operations. They can effectively manage multiple connections and reliably power large equipment. These features make them suitable for demanding construction environments.These environments have high power demands and safety is critical. These components are used in both fixed-mount and portable units. They are able to meet the complex needs of modern construction projects.