Address: No. 199, Weiwu Road, Yueqing Economic Development Zone, Zhejiang Province, China.

With the continuous development of automation technology, industrial equipment has higher and higher requirements for connectors. Especially in the fields of automated production lines, robotic systems, sensor equipment and intelligent manufacturing, the stability and reliability of connectors have become key factors in ensuring the normal operation of equipment. As an important connection solution, industrial multi-plugs have become an indispensable part of modern automation equipment with their excellent performance.

I. Do you really understand industrial multi-plugs?

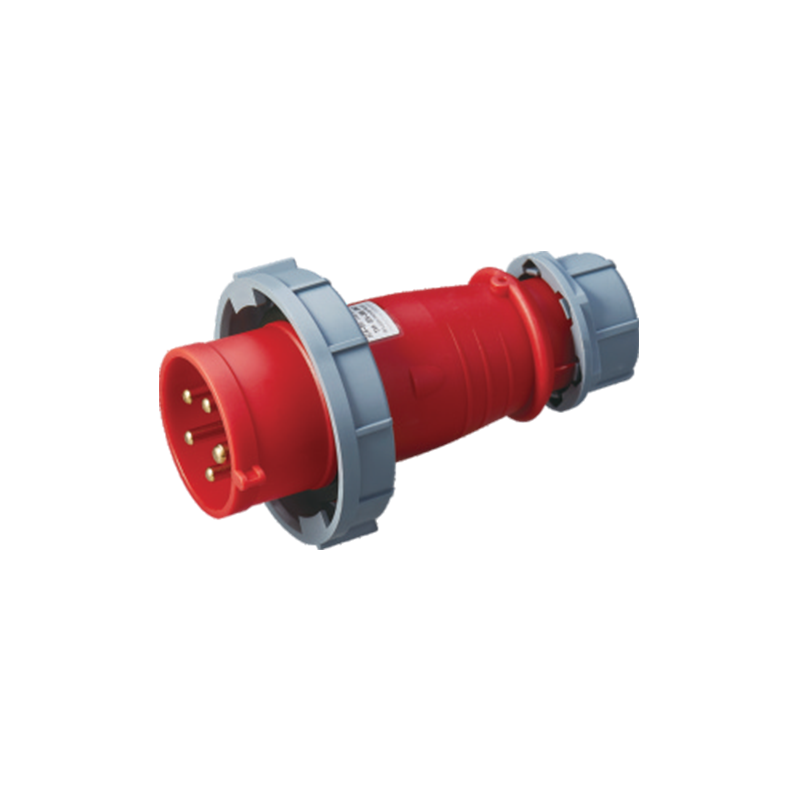

Industrial multi-plugs, as the name suggests, refer to plugs that integrate multiple pins or contact points in one connector. This design can provide multiple electrical connections in a limited space and is widely used in various industrial equipment. The core advantage of industrial multi-plugs is that they can achieve high-density connections while having excellent durability and anti-interference capabilities.

II. Advantages of industrial multi-plugs in automation equipment

1. High reliability

In automation equipment, any connection failure may cause the entire system to stop operating, causing huge economic losses. However, the use of industrial multi-plugs can avoid most of the problems encountered. Industrial multi-plugs use high-quality materials and precise manufacturing processes to ensure high reliability in long-term use. Many high-end industrial multi-plugs also have the characteristics of waterproof, dustproof, vibration-resistant and high temperature resistance, and can operate stably in harsh working environments, thereby reducing the failure rate and ensuring the normal operation of the equipment.

2. Low failure rate

The design of industrial multi-plugs emphasizes low failure rate. Its contact points are usually made of highly conductive metals, such as copper alloys or gold-plated materials, to ensure the stability of electrical connections. In addition, the precise plug-in design and durable contact materials effectively reduce the wear and poor contact problems caused by frequent use of connectors. This design can significantly reduce the downtime of equipment due to connector failure and improve the overall operating efficiency of the system.

3. High-density connection

The traditional single-plug connection method often requires multiple connection points, resulting in messy wiring and large space occupation. The industrial multi-plug can realize the connection of multiple signals and power supplies in a limited space by arranging multiple contact points at a high density. This is especially important for situations where a large number of connections are required in automation equipment, which can effectively save the internal space of the equipment, simplify wiring, and improve the space utilization of the production line.

4. Easy to maintain and replace

Since industrial multi-plugs have unified plug and socket standards, equipment maintenance personnel can easily replace and repair plugs, shortening equipment downtime. Compared with traditional multi-wiring methods, the modular design of industrial multi-plugs makes the connection simpler and faster, and is easy to achieve mass production and standardized operation.

III. Application scenarios of industrial multi-plugs

1. Automated production lines

In automated production lines, industrial multi-plugs are widely used in the connection of various equipment, such as sensors, robots, drive systems, PLC control systems, etc. They can realize the centralized connection of power, signals, data and control signals, simplify the layout and wiring of the system, and improve the reliability of equipment.

2. Robotic systems

Modern industrial robots usually require multiple electrical connection points to drive motors, sensors and other actuators. Industrial multi-plugs can integrate multiple connection points in one plug, simplify the electrical connection system of the robot, and improve the robot's operating efficiency and maintenance convenience.

3. Industrial control systems

In industrial automation control systems, PLCs, inverters, servo systems and other equipment need to be frequently electrically connected. Industrial multi-plugs provide these systems with an efficient and stable connection solution, avoiding the problems of poor contact and signal interference that may occur in traditional wiring methods.

Industrial multi-plugs are used in all aspects. The wide use of this product not only improves the connection efficiency of equipment and the stability of the system, but also effectively reduces the failure rate of equipment and extends the service life of equipment. With their high reliability, low failure rate, high-density connection, and easy maintenance, they have become an indispensable and important part of modern automated production lines and intelligent manufacturing systems.